1955 – 1956 Dodge & Plymouth

Custom Performance Exhaust System

Introduction

In this article, I detail my design and fabrication of the exhaust system for my 1956 Dodge coupe, although the build can be applied to any classic vehicle. While the article focuses on my design and fabrication for this car, the article applies to classic vehicle exhaust systems in general. In another article, I go into great detail about the individual components of an exhaust system and parts selection and focus on the fabrication in this article. Because I replaced the factory low-performance 270 poly engine with a stout A-block poly 390 stroker that will see track time, I needed to upgrade the exhaust to assist the engine and make use of its potential . For stock engines, a stock exhaust system works just fine; for mild and high-performance engines, the factory 1955/1956 Mopar exhaust system is restrictive and harms performance. While I cover exhaust manifolds and headers in another article, this article focuses on rebuilding the exhaust system from the exhaust manifold/header collector flange back through the head pipes, mufflers, and tailpipes.

To give a practical example of designing and fabricating an exhaust system, I’ll go through the work I did on my 1956 Dodge coupe. While I don’t profess to know all the available exhaust kits for these cars, there are limited prefabricated kits for those who want to do the installation themselves, particularly for larger-diameter systems for high-performance engines. There may be kits that fit well, so please email me if you have personally used a good kit so I may include the information. Of course, a quality exhaust shop can bend up and install an exhaust system for our cars, but prices for this service have greatly risen commensurate with labor rates and material costs. Since I prefer to do my own work, I was faced with finding the best prefabricated bends at an economical enough cost to make doing the work myself worthwhile.

Parts Selection

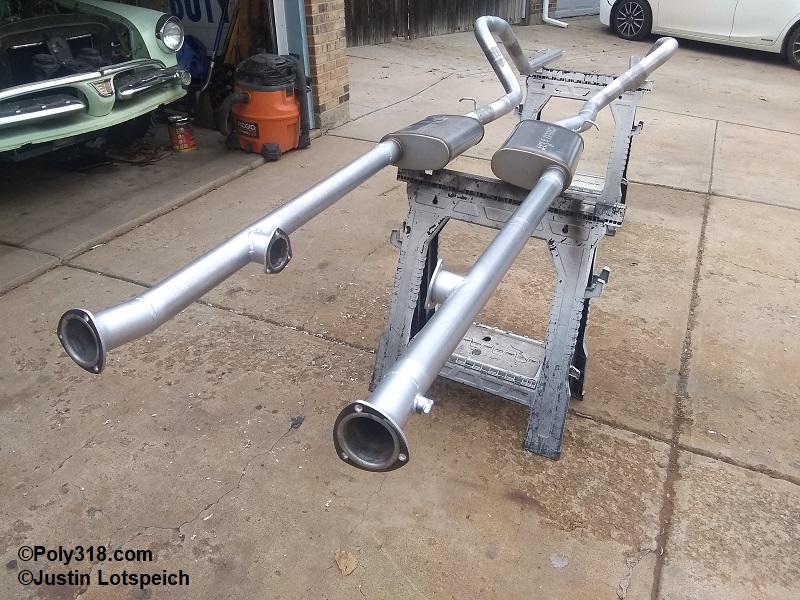

I wanted mandrel bends, 14-gauge mild steel, 2.5″ diameter, but purchasing enough individual bends, straight sticks, and collector reducers and flanges added up to an unreasonable cost for a self-designed system, so I researched available universal and model-specific kits for classic cars across all brands. After evaluating the options available, I chose a 1968 – 1974 Mopar B-body 2.5″ diameter kit from JEGS, #30503 for $370 after tax shipped as of 2022 (Figure 1a – 1b). The tubing was quality 14-gauge aluminized steel and welded well with argon MIG well. The female sockets were well-formed and not too oversized beyond light peening. The mandrel bends were well-formed with no crushing. I purchased an additional 8′ of straight tubing for the head pipes rather than using the provided offset head pipes due to the position of the headers I built. The provided bends also allowed me to properly route up over the rear axle and correct what I find is an inconvenience in the factory routing that runs too tightly under the gas tank and makes removal and instillation more complicated than it needs to be.

For mufflers, I chose 2.5″ Cherry Bomb “Salute,” which is a turbo-glasspack hybrid with an offset inlet and center outlet, although the muffler is reversible in direction (Figure 1c). I went with the Salute after hearing them idling in the pits and going down the 1/4-mile track and liking how they have a slightly deeper classic tone than a turbo and a volume about halfway between a turbo (a little too quiet to me) and a dual-chamber muffler (louder than I want on longer street cruises and for my neighbors to put up with in the early morning or late at night). The muffler was well built from heavy gauge stainless steel and welded joints, and it produced clean welds to the aluminized steel tubing with argon MIG.

Note that in some of the following photos, I show the exhaust clamped with u-bolt clamps and tack welds, but the finished system is fully welded with no u-bolt clamps. I use the clamps during fabrication to crimp the female sockets just enough to hold the tubes in place as I manipulate their positions. I use rebar tie-wire to raise/lower the tubing, pull the components toward/away from the chassis and components, and to hold the mufflers level from rotating. To maintain tight clearances, I use a combination of wood blocks or rags to hold the tubing away from the object during tack-welding.

Construction

Before beginning the system design and construction, I had to address the rear bumper. Taking the time to dial in the bumper is crucial since a bumper out of adjustment will result in incorrect tailpipe and tip placement. I carefully measured and adjusted the bumper to ensure both sides were located evenly away from the fins (Figure 1d), even in elevation from top of fin down, centered from side to side, and that the wrap-arounds were located just under the recess in the quarter panel (3/8″ down in my case) and parallel to the recess line (Figure 1e). Likely from the factory since I found no sign of damage or bent brackets and I’ve already confirmed the chassis is not diamond when I built the Dakota front clip, one side of my bumper was 3/8″ too far out at its adjustment limits. I had to remove that side’s bracket and elongate the three holes in the frame rail to allow the bracket to slide 3/8″ farther forward to both match the other side and to close the visible gap between the bumper and valence. I used 1956 photographs to determine where all the bumper lines rested from the factory. If I had not taken the time to adjusted the bumper and built the tailpipes and tips around it, when I adjusted the bumper during body work before paint one tip would be 3/8″ longer than the other–a noticeable issue with such tight clearances to the bumper.

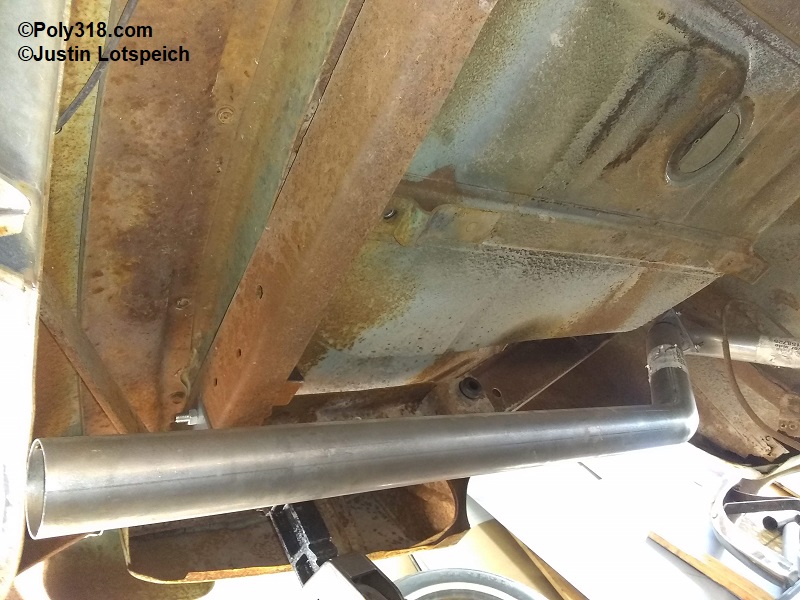

Coming out of the 3″ header collectors, I used the reducers included in the JEGS kit. I cut the head pipe and reducer butt-joint at a slight angle to point the head pipe toward the muffler inlet. I ran the head pipes into the mufflers with the inlets positioned toward their respective frame rails (Figure 1f). I will build and cut in the “H” crossover at a later time, which I detail in the next section. I played with the elevation of the mufflers to where they were not visible from viewing the car from the side but were low enough to keep excessive heat and noise out of the cabin. Running the head pipes straight back with the muffler inlets toward the frame rails placed the mufflers and tubes away from the drive shaft, close to the factory locations, and positioned where the parking-brake cable had enough room to clear between the muffler and frame rail.

Coming out of the left (driver) muffler, I used the short jog with the most offset (far right in Figure 1a) to move toward the left frame rail, followed by the pre-axle “S” bend marked “driver side,” and the tailpipe marked “driver side” (Figures 1g – 1i). In routing over the axle to clear the shock absorber, gas tank, and to provide ample clearance above the axle housing, I had to removed the left axle bumper bolted to the bottom of the chassis and rotate the tubes in a way that placed the hump’s apex just under the frame rail but not hanging out past the outside of the rail where it would interfere with a wide tire. A reader may think that removing the axle bumper and placing the exhaust in its place is a bad idea, but I checked that even with the most extreme amount of passenger load and bouncing the rear bumper, there is 10″ of clearance between the top of the axle and the bottom of the exhaust tube, and the inner body wheel well bottoms out on the tire with 6″ clearance left between the axle and exhaust tube. With no threat of making contact, the rubber bumper is useless since the chassis and exhaust is in no danger of making contact with the axle.

With the tailpipe routed this way, I was able to bring it out the back straight/parallel with the body, between the gas tank side and leaf spring, and aesthetically pleasing up close to the bottom of the bumper. This routing also provided more room between the gas tank and the exhaust to make tank installation/removal much easier than with the factory routing since to remove/install the tank off of the filler neck requires pushing the tank toward the left side. Something to keep in mind is that the clearance in this area is tight with 1/4″ between the tubing and the left-front side seam flange of the gas tank and 1/2″ between the side of the leaf spring shackle bolt. While this is enough clearance since I secured the exhaust well with hangers, I took the precaution of bending up a 2″ section of the gas tank seam like the factory did at the hold-down straps, which gave me 1/2″ total clearance. By the time the exhaust reaches this area, the tube is only warm to the touch with no danger of a fire hazard. The leaf spring under heavy bouncing clears the tube, but a very slight dimpling of the tube if I find rubbing after test driving will resolve any rubbing and not impact performance being at the very end of the run.

For the right (passenger) side coming out of the muffler, I used the short jog with the least offset to move the tube away from the right frame rail, followed by the pre-axle “S” bend marked “passenger side,” and the tailpipe marked “passenger side” (Figures 1j – 1l). I rotated the tubes to where the apex of the hump over the axle rested below the frame rail similar to the left side but farther inside. I will abandon the chassis rubber bumper on the right side as well since it isn’t needed. This position placed the tailpipe on the outside of the spare-tire well, parallel with the body and left tailpipe, and evenly located off the center of the body equal to the left tailpipe. Placing the tailpipe outlets took a lot of trial and error to get the correct location with a slope that looked good when viewing the car from the side and rear. After I triple-checked all the system’s clearances and positioning, I placed four tack-welds on each of the joints from the muffler outlet back to hold everything in place but left the head pipes loose to fabricate the “H” crossover, which I detail in the next section. Figure 1m shows the two legs completed.

Tailpipe Decorative Tip:

For the 1955 – 1956 Dodge and Plymouth with a gloss paint job, I prefer round polished tips with a rolled edge and that are stainless steel to resist corrosion from exhaust water and acids. In the 1950s, Mopar offered an attractive oval tip with vertical bars, but reproduction tips in this style drastically reduce the square inches below the 4.40 square inches of the 2.5″ tubing. The round tip slides over the outside of the exhaust tube and is welded in place around the perimeter of the front (toward the engine) of the sleeve. One thing that bothers me aesthetically is when people simply slide these tips onto the existing tailpipe without trimming the outlet back beyond the view of someone standing about 10′ away. Not trimming back the tailpipe creates an unsightly double-wall that quickly draws the eye way from the rear body features since it looks out of place (Figure 1n). Another issue with keeping the mild-steel tubing inside most of the tip sleeve is that the exhaust water and acid pools between the sleeve and rots out the mild steel since the tip’s rolled edge stops the water from draining off the back. The rusting steel bulges up inside the tube and pushes out the bottom and sides of the tip sleeve. If the tip is chromed steel, it too rots out.

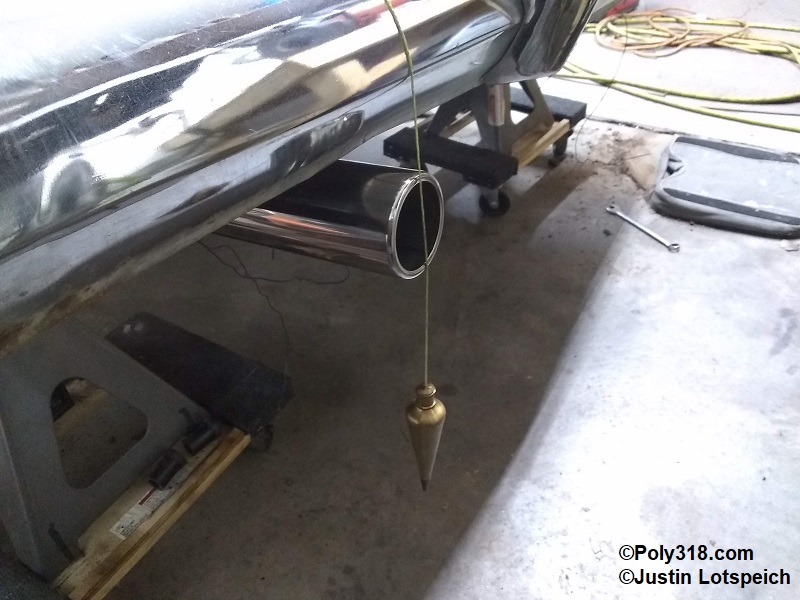

For placement, I dropped a plumb bob to mark the bumper apex as a benchmark and moved the sleeve forward and back while stepping back to view from all angles until I found an aesthetic sweet spot 1/2″ past the bumper apex (Figure 1o). This position will likely cause some soot to build up on the bumper over time due to idling that will easily wipe off, but moving it out far enough to stop the buildup looks ugly to me since the tips break up the curve of the bumper and protrude far enough to catch on one’s leg when entering the trunk. I marked the tailpipe at the front (toward the engine) of the sleeve, removed the sleeve, and made another mark 2.5″ farther toward rear. I cut the tailpipe at this mark so that when the tip is welded in place the mild-steel tailpipe extends only 2.5″ into the sleeve, is hidden,and keeps the mild-steel tubing away from the exhaust water and acids to prevent corrosion.

I stitch-welded the tip at the front (toward the engine) with three 1″ beads making sure to not weld the very bottom of the joint. My reasoning for welding in this way was because the joint is not structural, it does not need a seal, to limit the heat affected zone so as to not discolor the stainless steel blue/purple where it would be visible, and to leave the bottom open so exhaust water and acids can drain out the front (toward the engine) and not pool and corrode the mild-steel tailpipe.

Fabricating the “H” Crossover:

See my other article on exhaust that discusses why I am using an “H” crossover. I had the two mid-length tubes from the JEGS kit (the top of Figure 1a above), and one of them had a shallow bend in it that forms a “V” that would work nicely under the transmission tail housing long enough to span between both exhaust head pipes. I was able to locate the crossover 14″ behind the start of the head pipe/header flange for enough clearance around the transmission and to allow enough room around the drop-out connectors. I marked each head pipe for that location pulling the measurements off chassis points that I knew would place the crossover square with the chassis rather than relying on the header flanges. I chose to build a bolt-in crossover so I can easily install and remove the transmission without having to drop the exhaust. I first cut two 3″ long pieces of straight 2.5″ diameter tubing from some drops and used the cutoff wheel and then sanding disc to notch a bird’s mouth into one end of each piece. Placing the bird’s mouth up against the head pipes under the car, I traced the outside of the bird’s mouth onto the head pipe with a permanent marker and noted a “left” and “right” onto the head pipes and short pieces. After removing the head pipes, I used a hole saw to cut out most of the area and a carbide bit in a pneumatic die grinder to bring the hole out to just before the permanent marker line and de-burred the inside of the tubes.

To assemble the components, I tack-welded the short pieces onto their respective head pipes, placed the 3-bolt flange onto the short tubes, and tack-welded the inside of the flange to the tube in an even orientation with the single bolt facing up. I slid the head pipes into the mufflers, secured them to the headers, and took the measurement from the inside of one head pipe to the inside of the other (not the flanges). I cut the crossover tube with the subtle “V” centered over the tail housing to this measurement minus 1/2″ to allow for temporary fitment. I placed the crossover up against the sides of the short flanges on the head pipes and rotated the head pipes until the short flanged tubes were at the same downward angle as the “V” crossover. I marked the side of the crossover with permanent marker at both of the flanges. I subtracted 1/8″ off each side of the marks to account for a 1/16″ gasket and 1/16″ so the crossover would rest 1/16″ inside the flanges not yet welded on. After cutting the crossover tube square, I bolted the gasket and second set of flanges to the head pipe flanges and slipped in the crossover pipe. I rotated the crossover tube so the “V” pointed down and placed three small tack welds to secure the crossover to its flanges. At this point, I marked the head-pipe reducers where I would drill the holes for the oxygen sensor bungs since I use an oxygen sensor to tune the dual carburetors. I removed the head pipe/crossover assembly, finished the welds, drilled the oxygen sensor holes, and welded on those bungs (Figures 1p – 1q). I installed the assembly, checked that everything was aligned and bolted down, and tack-welded the head pipes to the muffler inlets.

Hanger Placement and Final Welding:

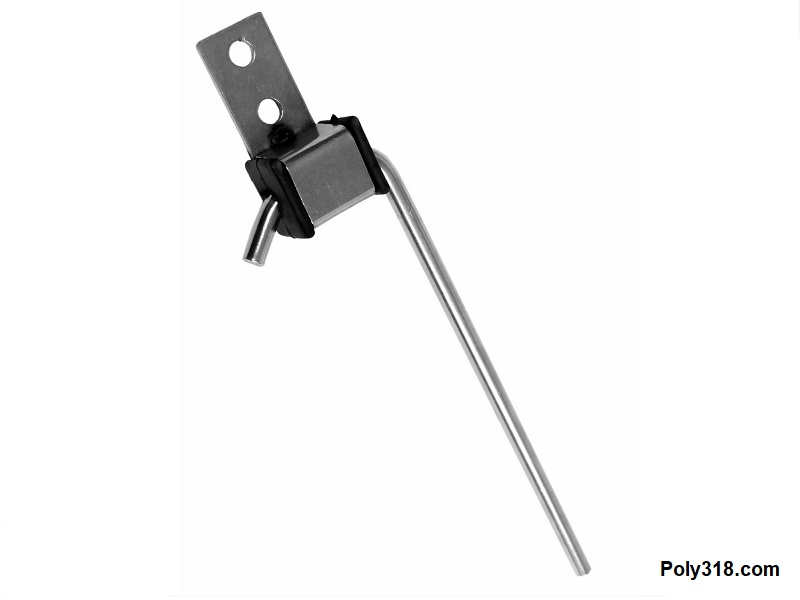

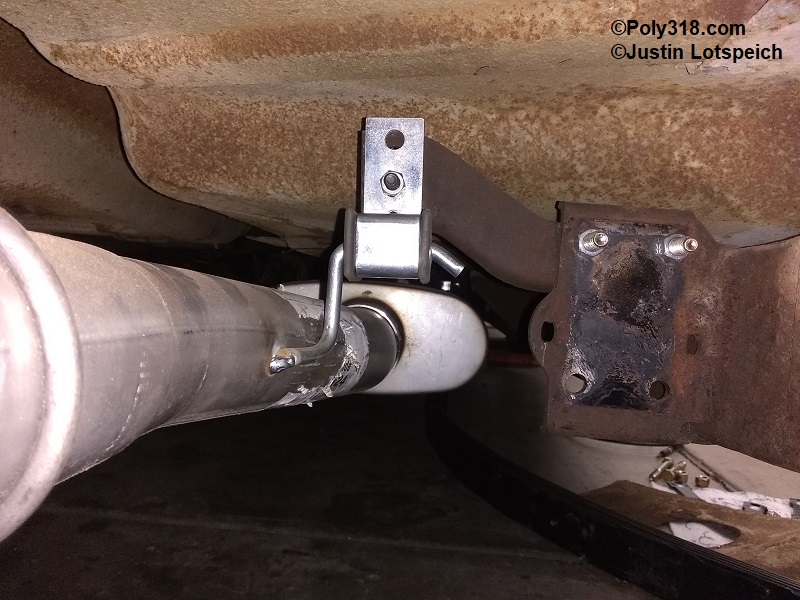

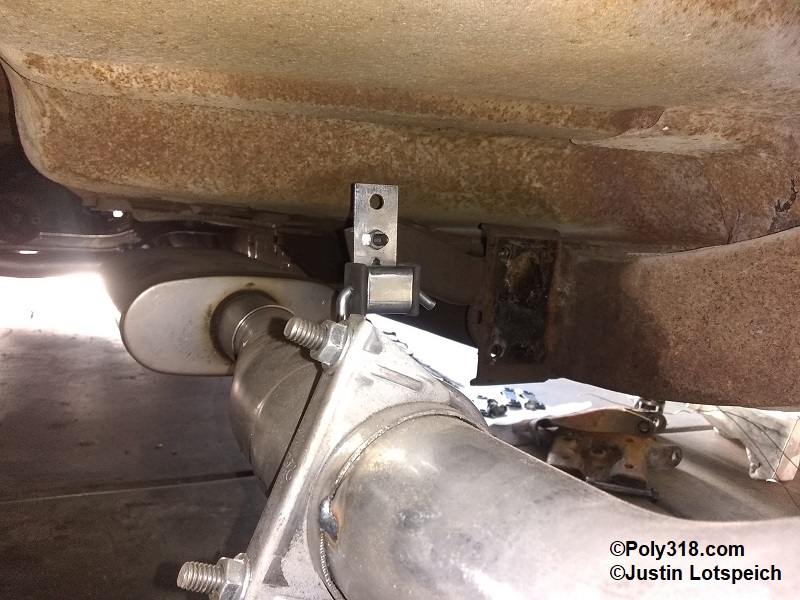

With the entire exhaust system now tack-welded, I focused on the hangers. There is no standard for the quantity of hangers, but the system should be very well supported to where it does not move around excessively and that unnecessary stress is not placed on components. If anyone is curious, the factory 1955 – 1956 Dodge/Plymouth design used two hangers–one behind the mufflers and the other at the tailpipes. The hangers I like using have a straight 3/8″ hardened stainless steel rod that hangs down from a sturdy rubber damper mount (Figure 1r). For the mid-system hangers that support closest to the mufflers, I used the leaf spring front mounting brackets as anchors. I bolted the hanger mount to the factory bracket on the right side and built a similar bracket for the left side (Figures 1s – 1t). I installed the hanger rod into the damper mount and marked it with a permanent marker at the center of the exhaust tube, placed the rod in a vice, heated the marked area with a torch, and used a piece of scrap pipe slipped over the hanger rod to bend a 90° turn. I cut off the rod leaving a 3″ leg. I installed the rod into the hanger and tack-welded the leg onto the tube similar to Figure 1s. For the tailpipe hanger, I was coincidentally able to use existing holes in the the back crossmember for the hanger mounts and bent, cut, and tack-welded the hanger rods to the tailpipe. With the temporary tie-wires removed allowing the system to hang from the headers, the middle hanger, and the rear hanger, I shook the entire length of the system and found it was held solid in place with no need for a third hanger before the mufflers.

With all the components tack-welded, I removed the system and finished the welds (Figure 1u). After finishing the welds, I cleaned up any spatter with a sanding disc, wire brushed all the joints to remove welding residue, and wiped those areas with lacquer thinner. I applied two coats of high-temp “aluminum” color spray paint (Figures 1v – 1w). I used a gasket scraper to remove the JEGS stickers. While I cover the process of fitting and welding the stainless tips, I do this at the very end after reinstalling the system.