1949 – 1959 Dodge, Plymouth, Chrysler, DeSoto

Oil Pressure Hose Fabrication

Introduction

The factory oil pressure gauge on 1949 – 1959 Dodge, Plymouth, Chrysler, and DeSoto vehicles can present an issue for both people operating the vehicles and for those restoring them. Mopar was ahead of many American manufacturers in that they used a hose from the gauge to the port in the engine block while other manufacturers used copper tubing. The engine rolls during acceleration and deceleration, and this motion moves the tubing or hose up and down. The movement increases with warn motor and transmission mounts. While copper tubing is forgiving, especially when a couple coils are bent into the tubing before it passes through the firewall, the continuous movement work-hardens the tubing and can lead to cracking. The tubing is known to fracture at either the engine connection or the gauge connection. If the tubing fractures at the engine, oil can shoot onto the hot exhaust and create a fire, aside from making a terrible mess in the engine bay if no fire starts; if the tubing fractures at the gauge, the driver, passengers, and interior can be sprayed and scalded by oil. To mitigate these issues, Mopar used a rubber hose, which largely resolves the issue until the hose deteriorates and ruptures.

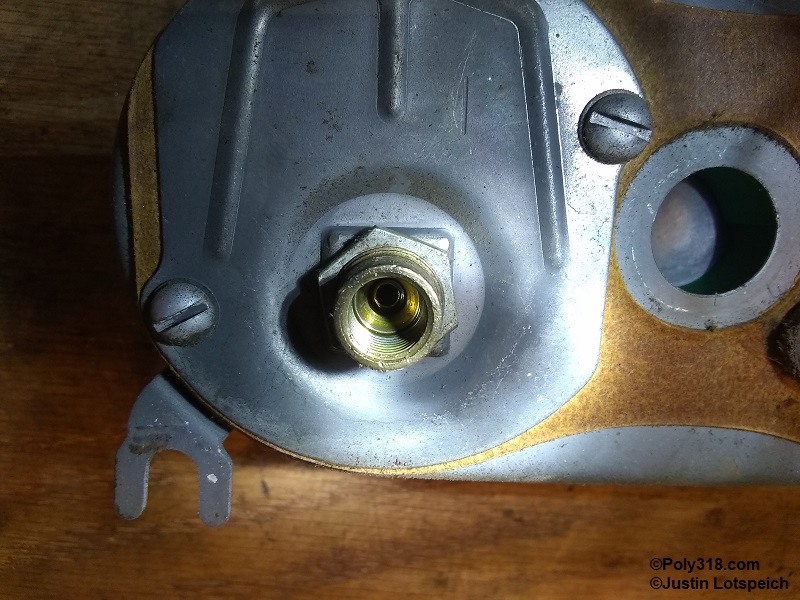

The factory hose is an oddball design that uses a 7/16”-24 female double inverted flare fitting at the engine port and a short length of 3/16” steel line with a one-off bell ferrule soldered to the tubing and a 3/8”-27 straight-thread nut at the gauge (Figures 1 – 3). The gauge has a concave ferrule inserted into the port (Figure 4). To be clear, the gauge nut is not a 3/8”-24 double inverted flare nut used on 3/16” line, nor is it pipe thread. I also tried a M10 x 1.0 metric fitting that did not thread in at all and a -3 AN that threaded in a couple threads before wanting to cross-threading. I cannot source this type of nut after calling every fitting manufacturer I could think of. To make matters worse, most aftermarket OEM-type hoses do not include the unique nut and ferrule (Figure 5), and the sellers don’t offer the nut or ferrule separately. To use an aftermarket OEM-type hose that doesn’t include the nut and ferrule, one must either already have a hose that can be cannibalized for the nut and ferrule—hoping the ferrule is reusable—, purchase a used hose to cannibalize, or purchase a NOS hose. In this article, I provide an alternative solution that I built for my 1956 Dodge coupe that looks clean, inconspicuous, and is stronger than the OEM design.

Fabricating the Oil Pressure Hose Assembly

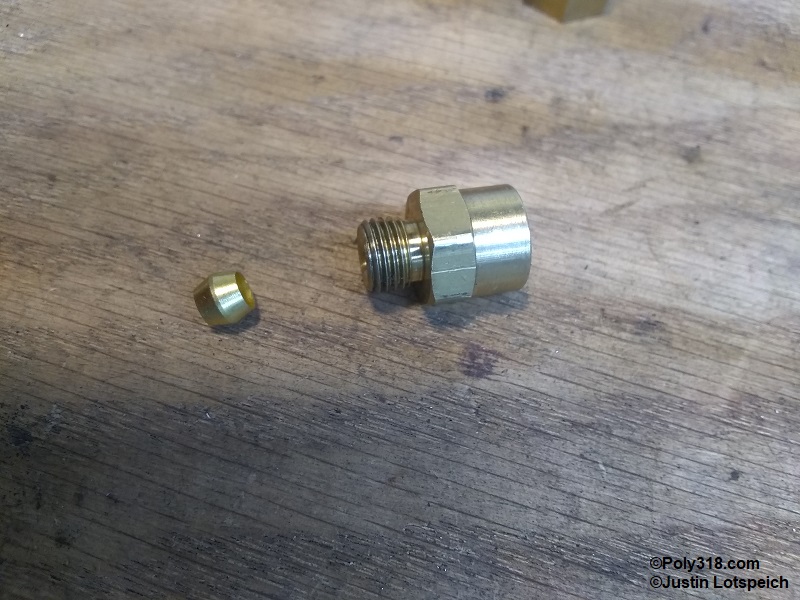

After experimenting, the only fitting I could find that shares the 3/8”-27 straight threads is the male threads of a 3/16” compression fitting that accepts the compression nut. I obtained an Edelmann 166320 3/16” tubing to 1/8”-27 female NPT compression fitting that includes the ferrule and nut (Figure 6). I could not source a 3/16″ compression to -3 AN adapter that would be the cleanest method.

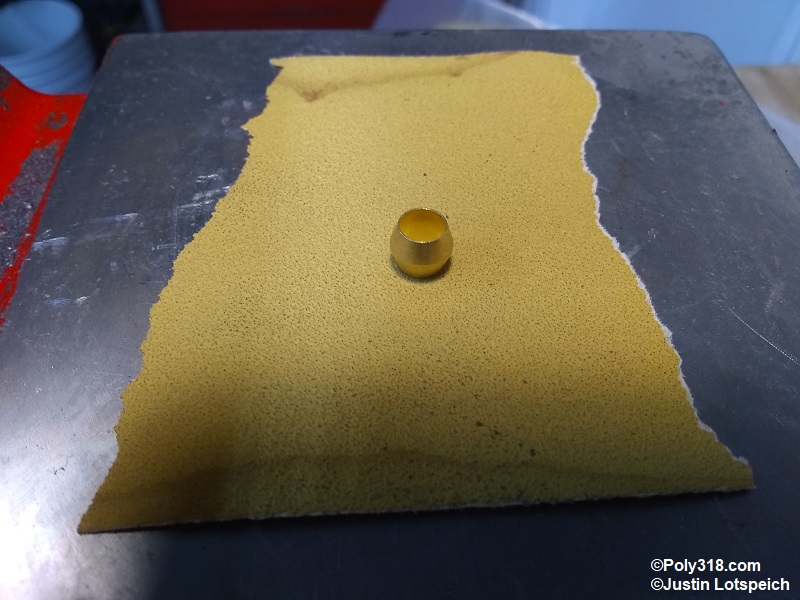

After fitting the ferrule into the gauge fitting and examining it with a magnifying glass, I noticed that the fitting ferrule’s tapered sealing surface was not touching the gauge’s concave ferrule because the fitting ferrule was too long. I used a micrometer to measure the ferrule at 0.225” long. With a piece of sandpaper laid flat, I sanded one side of the ferrule evenly until the ferrule measured 0.20” (Figures 7 – 8). After using a file to smooth the ferrule’s edge of burrs and blowing it off with compressed air, I dropped it into the gauge fitting sanded side toward the gauge and found that the male and female tapers touched well enough for compression.

I slowly tightened the compression fitting into the gauge until I felt the ferrule seat. If the gauge fitting tries to turn, tighten the jam nut. The ferrule seated nicely just when I ran out of threads (Figure 9). An alternative plan I had if the fitting threads were not long enough or the ferrule did not seat well was to use a copper sealing washer between the fitting and rim of the gauge inlet.

From the compression fitting, I used a steel Fragola 581603 male -3 AN to 1/8”-27 male NPT adapter with Teflon tape on the pipe threads (Figure 10). I do not recommend using an aluminum fitting here since it is a small fitting and the hose weight and vibration may eventually fracture it.

I used a piece of rebar tie wire to route from the engine port to the gauge along my desired path, straightened the wire, and measured it at 28”. The closest prefabricated -3 AN 3/16” braided stainless brake hose with black PVC coating and black anodized fittings that I could find was a 30″ Allstar 48366 (Figure 11). I chose straight AN fitting since they worked with the routing, although Allstar offers 90° fittings. I’ve used Allstar 3/8”, 5/16”, and 3/16” steel hard lines and fitting before and have been impressed by the quality, and the braided brake hose I received was high quality. The black coating and fittings are inconspicuous compared to silver braided stainless steel and fittings and blend in nicely with stock and period-correct builds.

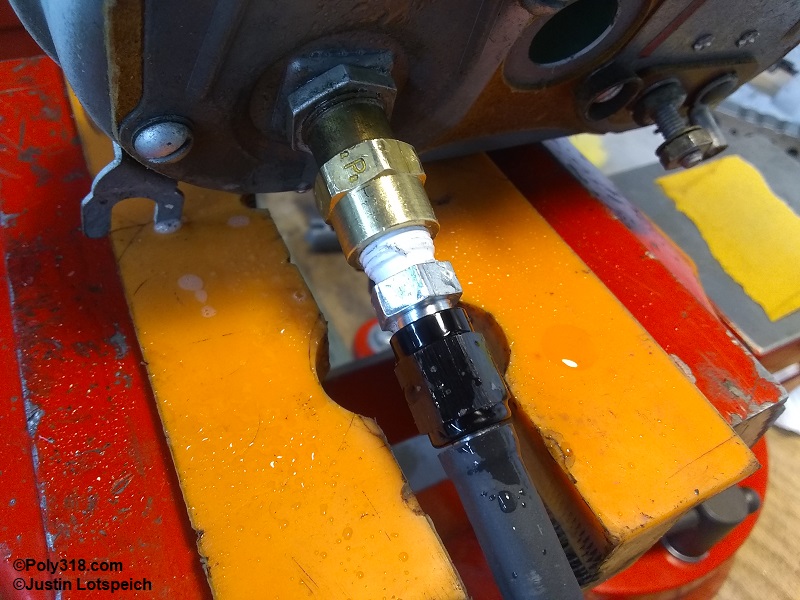

At the engine port, which is a 1/8”-27 female NPT for the poly A-block engine I’m running, I used another steel Fragola 581603 male -3 AN to 1/8”-27 male NPT adapter. I do not recommend using an aluminum fitting here since the hose weight and vibration may eventually fracture it. For engines with a 1/4″-18 NPT port, use a Nitrous Express 16110 or similar steel or stainless steel fitting.

To test the assembly’s seals, I used Teflon tape to install a 1/4″-18 male NPT to 1/8”-27 female NPT reducer onto the engine fitting followed by a 1/4″-18 female air-compressor fitting (Figure 12). For setups with a 1/4″-18 NPT engine adapter, simply attach the air-compressor fitting directly to the engine adapter.

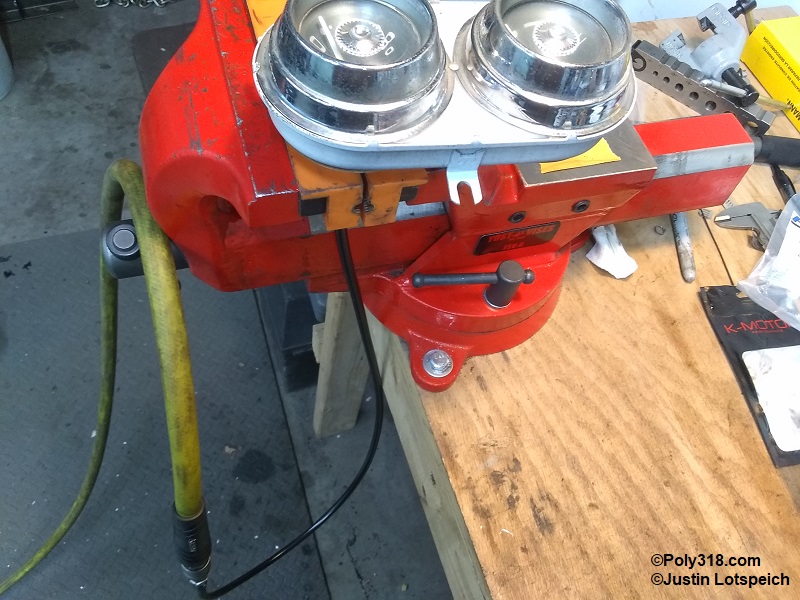

I secured the gauge in the bench vise with rubber soft jaws, set my air regulator to 10 psi, and attached the hose. I checked the gauge to see that it was reading just off the 0 mark before increasing the regulator until the gauge just hit the maximum mark of 80 psi, which was also 80 on the air regulator (Figures 13 – 15). Keep in mind the highest pressure my engine will see at operating temperature under throttle with the high-pressure pump and oil viscosity I am running will be between 65 – 72 psi. Cold-start pressure will be higher though and will likely reach 80 psi for a limited time until the oil begins warming. either way, 80 psi is plenty of pressure for testing.

Holding 80 psi in the air line, I sprayed the fittings at the gauge with soapy water and checked carefully for bubbles; I was pleased that none appeared (Figure 16). I left the gauge under pressure for twelve hours going back to check the fittings and apply more soapy water, and no bubbles appeared. I left the gauge under pressure overnight and reapplied soapy water again and found no leaks. At this point, I was ready to remove the air hose and fittings, wipe off the fittings of any residual soap, install the -3 AN adapter into the engine, slide the hose through the grommet in the firewall, and hook up the system to the engine fitting. In general, when the hose is installed it should have plenty of slack at the back of the engine and gauge for movement, and it should be well supported with Adel clamps or zip-ties under the dashboard to limit movement, protect from rub points, and take strain off of the gauge fittings.

Concluding Thoughts

I was able to purchase all the fittings and brake hose for under $30, and the AN setup is both easy to install and stronger and more resilient to wear than the OEM hose. For museum-quality restorations, my alternative setup won’t do, but for those not concerned with OEM aesthetics and especially those who don’t have the factory gauge nut and ferrule to use on an aftermarket hose, it’s a viable option. Having the protection of braided stainless steel hose is also an added benefit both in the engine compartment and cabin.