Poly 318 Camshafts

(applicable to 277, 301, 303, 313, 318, 326, 390, 402, 408 engines)

Introduction

This page discusses poly 318 and other A-block camshaft profiles, regrinding, and lifters. While the 1957 – 1958 “Dual Fury V-800” poly 318 boasted the hottest factory bump-stick, it was still terribly undersized for what the engine can make use of with factory spec equipment and certainly for high-performance builds. While mainstream cam manufacturers have given up on the A-block and we have lost some cam grinders like Chris Nielson (2017), we are lucky to have some custom cam grinders still around, including Schneider, CamCraft, and Racer Brown. Do not throw out old A-block camshafts since blanks are no longer produced and a regrind might be the most viable option. Cam profile selection is a precise process that depends on multiple vehicle variables from the engine back to the rear tires and should be discussed with the cam grinder. The following profiles are ballpark examples and should not be considered the definitive cams for every application. All specs below are with factory 1.5:1 ratio rocker arms.

How Regrinding a Camshaft Works

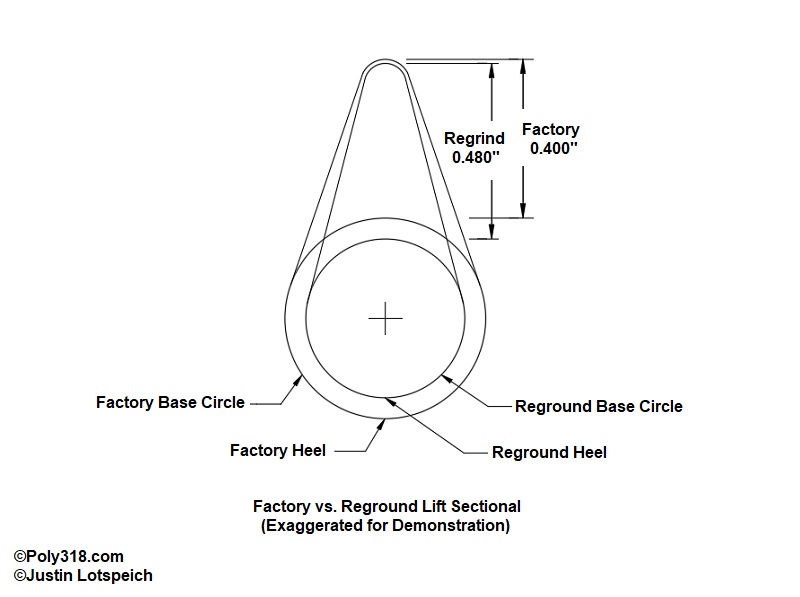

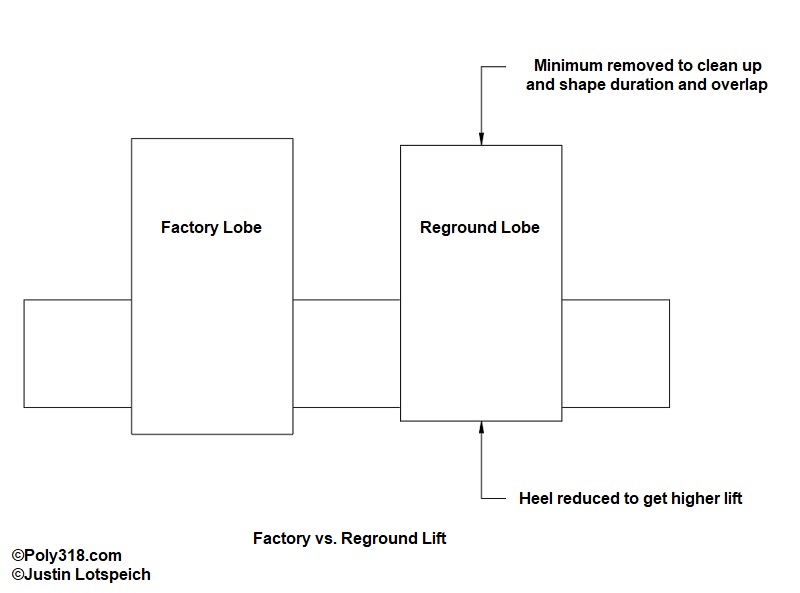

One might wonder how a factory camshaft with low lift can be reground to a profile with higher lift since logic says you cannot take away material to add material; however, cam grinders use geometry to get the job done. I drew Figures 1a and 1b to demonstrate how a factory camshaft with 0.400″ lift can be reground to 0.480″ lift. Notice how much the base circle of the factory lobe extends farther off of the center of the camshaft than the reground profile. The cam grinder gets the additional .080″ of lift in our example plus whatever is necessary to clean up and shape the nose of the lobe by reducing the base circle, thus adding lift. At the same time, the cam grinder can modify the duration and to a more limited extent overlap as much as the available material allows. Note that because the heel is now shorter due to the smaller diameter base circle, the lifter will rest lower in the lifter bore when the valve is fully closed requiring a longer pushrod if there is not enough adjustment in the rocker arms.

For regrinds on camshafts that do not have enough base-circle or overall lobe material to allow for the desired lift, duration, and/or overlap, the cam grinder welds on the lobes to add material, grinds the desired profile, and hardens the lobes as needed.

Billet Steel Camshafts

Having a camshaft producer build a custom billet camshaft is another option. This option is most commonly used for roller lifters. Because the billet camshaft route for flat-tappet lifters is expensive, it would be wise to spend the time and money converting the lifters to roller and have a roller profile built. Luckily for us A-block enthusiasts, the LA billet camshaft blank can be ground into most A-block profiles and does not require a custom blank to be created. Also, Mopar kept the A-block lifter bore spacing of 1.760″ on center for the LA, so LA roller lifters may be used in the A-block. Prepare for sticker shock, however, since a roller camshaft and lifter setup is much more expensive than a flat-tappet setup. Schneider produces roller camshafts for the A-block and has a catalog of profiles.

A-block and LA Camshaft and Lifter Misinformation

Before we dive into camshaft profiles, I want to debunk two claims about LA camshafts and lifters that float around online: A-block and LA camshafts do not interchange, and LA camshafts cannot be reground into an A-block configuration. The LA camshaft will physically slide into an A-block and accept the timing set, but LA lobes are configured starting at cylinder one running back of exhaust/intake/intake/exhaust; the A-block’s lobes are configured exhaust/intake/exhaust/intake (Figure 2a).

LA lifters are the same 0.904″ diameter as A-block lifters and will physically fit into the A-block lifter bores, but the LA lifters, depending on the manufacturer, are usually taller than A-block lifters. To use LA lifters in an A-block, like I did on my 390 stroker build, shorter custom-length pushrods are likely needed, which isn’t a bad idea to get new chrome moly pushrods anyway. There are only factory spec lifters available for the A-block, whereas there are many different options for LA lifters from variable-duration and anti-pump-up hydraulic to EDM oiling hole mechanical, so LA lifters are a good option paired with properly sized pushrods.

Factory Cam Profiles for Poly 318

“Dual Fury V800” 2×4-barrel

| Intake Duration (gross): | 256 |

| Exhaust Duration (gross): | 256 |

| Intake Duration (.050”): | 208 |

| Exhaust Duration (.050”): | 208 |

| Intake Valve Lift*: | .405″ |

| Exhaust Valve Lift*: | .405″ |

| Lobe Separation: | 110 |

| Valve Lash: | .017″ hot |

| RPM Range: | 1,800-5,500 |

“Fury V800 Super-Pak” 4-barrel and “Fury V800” 2-barrel

| Intake Duration (gross): | 240 |

| Exhaust Duration (gross): | 240 |

| Intake Duration (.050”): | 198 |

| Exhaust Duration (.050”): | 198 |

| Intake Valve Lift: | .400″ |

| Exhaust Valve Lift: | .400″ |

| Lobe Separation: | 111 |

| RPM Range | 1,500-4,400 |

Cam Profiles for Mild Street Poly 318

- 3.23:1 or lower gearing, slightly higher stall converter, and headers beneficial but not necessary. Mild lope with good vacuum.

- Contact the manufacturers for comparable hydraulic grind availability.

EH-2 (courtesy Racer Brown)

| Intake Duration (gross): | 264 |

| Exhaust Duration (gross): | 264 |

| Intake Duration (.050”): | 220 |

| Exhaust Duration (.050”): | 220 |

| Intake Valve Lift: | .450″ |

| Exhaust Valve Lift: | .450″ |

| Lobe Separation: | 110 |

| RPM Range: | 2,000-6,000 |

264H (courtesy Schneider)

| Intake Duration (gross): | 264 |

| Exhaust Duration (gross): | 264 |

| Intake Duration (.050”): | 208 |

| Exhaust Duration (.050”): | 208 |

| Intake Valve Lift: | .435″ |

| Exhaust Valve Lift: | .435″ |

| Lobe Separation: | 112 |

| RPM Range: | 1,800-4,800 |

Cam Profiles for Performance Street/Strip Poly 318 and Mild 390 or 402 Strokers

- 3.54 or lower gearing, headers, and high-stall converter necessary. Decent lope and vacuum.

- Warning: Checking valve clearance at or above .480” lift is a must with A-block pistons.

SSH50 (courtesy Racer Brown)

| Intake Duration (gross): | 274 |

| Exhaust Duration (gross): | 274 |

| Intake Duration (.050”): | 222 |

| Exhaust Duration (.050”): | 222 |

| Intake Valve Lift: | .477″ |

| Exhaust Valve Lift: | .477″ |

| Lobe Separation: | 110 |

| Mechanical Valve Lash: | 0.015″ hot |

| Hydraulic Valve Preload | 1/2 – 3/4 turn after 0 lash |

| RPM Range: | 2,400-6,500 |

274F (courtesy Schneider)

| Intake Duration (gross): | 274 |

| Exhaust Duration (gross): | 274 |

| Intake Duration (.050”): | 230 |

| Exhaust Duration (.050”): | 230 |

| Intake Valve Lift: | .480″ |

| Exhaust Valve Lift: | .480″ |

| Lobe Separation: | 110 |

| Mechanical Valve Lash: | 0.014″ hot |

| Hydraulic Valve Preload | 1/2 – 3/4 turn after 0 lash |

| RPM Range: | 2,500-6,500 |

Cam Profiles for High Performance Street/Strip 390 and 402 Strokers

- 3.73 or lower gearing, headers, and high-stall converter necessary. Strong lope with lower vacuum.

- Warning: Checking valve clearance at or above .480” lift is a must with A-block pistons.

SSH25 (courtesy Racer Brown)

| Intake Duration (gross): | 286 |

| Exhaust Duration (gross): | 286 |

| Intake Duration (.050”): | 238 |

| Exhaust Duration (.050”): | 238 |

| Intake Valve Lift: | .485″ |

| Exhaust Valve Lift: | .485″ |

| Lobe Separation: | 110 |

| Valve Lash: | 0.015″ hot |

| Hydraulic Valve Preload: | 1/2 – 3/4 turn after 0 lash |

| RPM Range: | 3,000-7,000 |

284F (courtesy Schneider Cams)

| Intake Duration (gross): | 284 |

| Exhaust Duration (gross): | 284 |

| Intake Duration (.050”): | 240 |

| Exhaust Duration (.050”): | 240 |

| Intake Valve Lift: | .480″ |

| Exhaust Valve Lift: | .480″ |

| Lobe Separation: | 110 |

| Mechanical Valve Lash: | 0.015″ hot |

| Hydraulic Valve Preload: | 1/2 – 3/4 turn after 0 lash |

| RPM Range: | 3,000-7,000 |

Acknowledgement

My thanks to the tech support at Schneider, CamCraft, Racer Brown, and Gary Pavlovich for fielding my questions on the following profiles and my description notes.