Poly 318 Intake and Exhaust Manifold Installation

(also applicable to all A-block and LA 273, 318, 340, and 360 engines)

Intake Manifold Installation

As part of my larger engine-building series, I want to cover installing intake and exhaust manifolds. After installing intakes a couple times, the processes becomes simple, but for those with less experience there are many steps that often are not covered when someone asks online. I usually read two-sentence responses for instructions like, “Cover the ports with RTV. Install the intake.”

The first thing to sort out is what type of intake gasket to use on the A318. Most suppliers including local parts stores carry only the OEM-style sheet metal gaskets that can be difficult to seal on aging heads/intakes with mating surfaces not as true as they were originally. The problem compounds if the head/intake/block has been machined and has wider clearances. Leaks can lead to oil migrating from the valley into the intake runners, vacuum leaks, and coolant leaks. The solution to the leaky metal gaskets is to either order fiber gaskets made by BEST brand or make intake gaskets out of a sheet of gasket material. Another benefit here is that gasket sheets come in different thicknesses. I either plan ahead and order the BEST gaskets, or if I am in a bind make my own to avoid any issues with the metal gaskets.

Making Intake Gaskets

First, I clean the intake mating surface of old sealant/oil/debris. Working at the bench, I place the gasket sheet against the intake surface, poke through the end bolt hole, push through a bolt and hand-tighten a nut, and chase the gasket to the other side until I have bolts in all the holes to keep things aligned and to locate the bolt holes. I take a sharp X-Acto knife and cut out the intake runners, water jacket, exhaust crossover, and trim up the perimeter. I block off the exhaust crossovers with sheet metal plugs but always cut the gasket anyway since I suspect that the hot exhaust would eventually degrade the gasket material to where it could flake off. Once finished and the gasket is removed, I blow out/off the intake with compressed air to remove any gasket debris.

Intake Installation

- Cover the lifter valley with clean paper towels or rags to catch any debris. Lightly plug the head intake runners and exhaust/coolant ports with crumpled paper towels, but make sure you are careful not to leave a bunch of fibers to suck into the chambers.

- Using a sharp gasket scraper and/or razor blade, scrape off all residual sealant, paint, grease, etc. from the sealing surfaces. I keep a paper towel in one hand to clean off the blade regularly to keep less debris from falling into the engine.

- Carefully remove all the head rags followed by the valley rags being careful not to drop debris into the engine.

- Clean the intake manifold surfaces of all debris if you have not already.

- I take a single-cut file or a confirmed flat sanding block with 80 grit paper and face the thermostat surface on both the intake and housing to true it up since they often corrode.

- Blow off the intake well with compressed air.

- Before I apply sealant and gaskets, I saturate the corner of a rag with lacquer thinner (brake clean works too), wrap it around my finger, and wipe all the sealing surfaces and the corners where the head and block meet to remove any grease/oil. Sealant does not stick to oil, so I go this extra step for a very clean surface.

- Double check the runners/ports and valley carefully for any debris.

- Before final installation, I dry fit the intake so I can check the end-rail gap. To do this, I place a dab of Permatex High Tack 80062 on each end of the cylinder head (a dab of RTV will work too). I lay the gasket onto the head and lower the intake manifold onto the gasket. I measure the gap between the block and the intake at the front rail. If the gap is more than 3/16” with the intake not torqued down, I cut end-rail gaskets out of a thick sheet of fiber gasket using the intake manifold as a template. If the gap is 3/16″ or less, I plan on using RTV. Lift off the intake manifold, lift off the gaskets, and wipe off any residual sealant from the temporary dabs with lacquer thinner or brake cleaner.

- For sealant and placement, there is plenty of debate. Unless the gasket manufacturer specifies installing the gasket dry, I seal around the water jackets, intake ports, exhaust crossover port, in the front and rear wall corners where the head and block meet, and on the end rails. I use Mopar RTV silicone 4883971, which has been tested to outperform all Permatex and other RTV silicone sealants both in tinsel and pressure strength.

- Working on one head at a time quickly to not allow the RTV to skin over, I squeeze and dab a thin (maybe 1/16” thick) 1/4″-wide line of RTV around the water jacket, intake ports, and exhaust crossover port on the head and use my nitrile-gloved index finger to even it out if necessary. I put on enough RTV to make a good seal but not enough to heavily ooze out into the jackets once torqued. Keep this line of sealant back about 1/16” from the edge when possible to allow room for the sealant to squeeze out without blocking the runners/ports.

- Squeeze a pea-sized glob of RTV into the corners of the front and rear walls where the head and block meet.

- Align the intake-to-head gasket at the bottom corners, push it into the glob of RTV in the corners, and gently swing it up onto the head surface. Align the gasket with the runners/bolt holes, and lightly press the gasket into the sealant on the head.

- Repeat on the other head.

- At this point, I would install the end-rail fiber gaskets if my dry fit found I needed it. I coat the block rail with RTV making sure to squeeze into the corners overlapping the side gaskets and then gently press the gasket into the RTV.

- If not using end-rail gaskets, I lay down a 1/4″-diameter bead of RTV on the rear and front end rails of the block making sure to press well into each of the corners overlapping the intake gaskets. Be aware that the A318 end-rail foam/rubber gaskets that come in the kits will usually slip out of place during torquing and often leak, so do not use them—hence all the work using RTV or cork.

- Using the same RTV process on the intake manifold, I place a bead of RTV around the water jacket/exhaust crossover/intake runner on the intake manifold. This is when I install the exhaust crossover block-off plates I cut out of 20-gauge sheet metal using dabs of RTV to hold them in place on the intake.

- Position the intake directly over the valley and slowly lower it into place aligning it as best as possible before making contact with the gaskets. As with many things, I am sure having two people would be helpful at this step with an iron intake, but it is doable solo.

- To clear up confusion, no intake bolts go through to coolant on an A-block head. Some are dead bosses, and others go through to the intake valley where there is potential of oil seeping up the threads and pooling atop the intake. It is easy enough to seal them, so I always do. However, a lot of people I see online use RTV or Teflon tape, which I hate for these bolts. Cured RTV is an irritating pain to clean off threads and out of threaded bosses, and removing the bolt and reinstalling them almost always drops crumbs of cured RTV into the engine that are terrible to clean out. Teflon tape shreds all over the place and can fall into the engine too when removing. I use RectorSeal T Plus 2, which is a PTFE-enriched paste sealant that I also use on the exhaust bolts that go through into the water jacket. It is designed for water and steam pipefitting, works well at high temps against oil and water seepage, and stays pliable for future removal/installation.

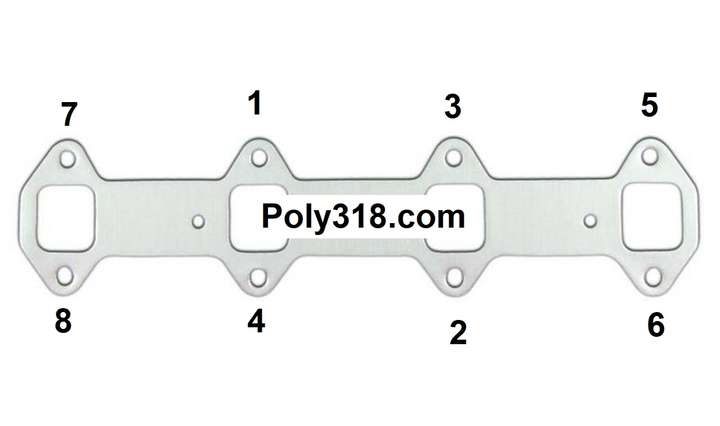

- I start all the bolts by hand and tighten evenly in three passes using the sequence in Figure 1. I tighten using a 6″ ratchet to where I feel the gaskets seat, but the factory iron spec is 30 ft. lbs. for anyone who wants to attempt (and likely fail) to get a torque wrench to fit around all the bolts.

- Some people wipe the silicone that pushes out from the front rail, but I leave it alone and let it form a “C” around the rail to help lock the RTV gasket in place. If I use a 1/4″-diameter bead, it is clean with no excessive amount flooding out, and I can trim off any unsightly area with a razor after the RTV is cured.

- I let the RTV cure for at least 24 hours and 48 if I can in weather above 60°F and 48 hours minimum below that temperature before filling the coolant and firing the engine, especially with RTV end rails. Silicone activates via oxygen, so leaving the water jackets empty will help speed up the process. If rushed, the outer skin of the end rails will appear cured, but the center of the RTV will still be wet and more likely to result in an oil leak.

- Now is a good time to adjust valves if needed since the covers are off and I have to wait for the RTV to cure (see my article on valve adjustment). Otherwise, I would install the valve covers, carburetor, accessories, distributor, and whatever else I had to remove. Connect any sensors/fittings/hoses that go into water jackets, but leave one hose disconnected from the intake or timing cover to use later.

- Wipe on a thin coat of RTV around the thermostat opening on the intake, center the thermostat spring-down, and gently press on the fiber gasket.

- Wipe a coat of RTV on the thermostat housing surface, and set the cleaned thermostat housing onto the manifold. I use a small dab of anti-seize compound on the thermostat bolts in case coolant ever weeps into the bosses. If using stainless-steel bolts in an aluminum intake, anti-seize is imperative to block galvanic corrosion. Hand tighten with a 6” 3/8 ratchet until I feel the gasket seat—likely no more than 20 in. lbs.

- Install the upper radiator hose.

- After the 24 – 48 hour cure, I fill the radiator until I see coolant appear near the top of the heater hose fitting I left open in the intake/timing cover. Install the heater hose or plug and fill the rest of the radiator. Using this method removes most air pockets from the engine.

- After a few heat cycles driving the vehicle, I retorque the intake manifold bolts when the engine is cold since they will likely be a little loose after heat cycles.

Exhaust Manifold Installation

Note on Permatex Ultra Copper 81878 RTV: In some applications that may leak, using a thin 1/16” coat of Ultra Copper RTV is acceptable. In some situations, particularly on a race engine when I expect to remove the headers more often, I have used Ultra Copper RTV in place of the gasket without sealing issues. Most situations should not require RTV, however. If using RTV, allow at least 48 hours cure.

- Lightly plug the exhaust runners with crumpled paper towels, but make sure not to leave a bunch of fibers to suck into the chamber via back-pressure.

- Using a sharp gasket scraper and/or razor blade, scrape off all residual gasket, paint, debris from the sealing surface.

- If using Ultra Copper RTV, wipe off the sealing surface with the corner of a rag saturated in lacquer thinner or brake clean.

- Remove all the rags being careful not to drop debris into the engine. Verify there is no debris in the runners.

- Clean the exhaust manifold/header mating surface in the same way.

- Blow off/out the exhaust manifold/header with compressed air to flush out any debris.

- Exhaust Studs: The lower row of threaded bosses goes through to coolant, and studs should be used since the stop bulge on the stud helps make the seal against the boss’s chamfered opening. The top row are blind holes and don’t require sealing. I prefer using studs on the bottom row and bolts on the top row for ease of installation. For the same reasons I explain regarding intake bolts, I discourage the use of RTV on the exhaust bolts. I use RectorSeal T Plus 2, which is a PTFE-enriched paste sealant designed for water and steam pipefitting, works well at high temps, and stays pliable for future removal/installation. Ensure that the stud and boss threads are clean of all debris and the chamfered opening is smooth, and coat the stud threads thoroughly to fill them. Run a 3/8″-24 nut up against the stop bulge finger tight, and run another nut up against that first nut. Install the stud, and place a socket on the outer-most nut to torque the stud to 30 lb.ft. When finished torquing, hold the inner-most nut with a wrench and remove the outer-most nut with the socket, then the inner nut.

- For all studs, slide the gaskets onto the studs, slide on the manifold/header, and start the nuts.

- For bottom studs with top bolts, slide the gasket onto the studs, install the manifold/header, and start the top bolts.

- Run down all the bolts/nuts finger tight and tighten using a three-step sequence of Figure 2 until the gasket seats. Do not overtighten since doing so can crack or break off the cast-iron ears.

- If Ultra Copper RTV is used, allow 24 hours (longer in temperatures below 60°F) for cure before starting the engine.

- After a few heat cycles of driving, retorque to bolts since they will likely be loose once the gaskets fully seat.