Poly 318 Intake Manifolds

Valve Covers

(Applicable to 277, 301, 303, 313, 318, 326, 390, 402 engines)

Factory Intake Manifolds

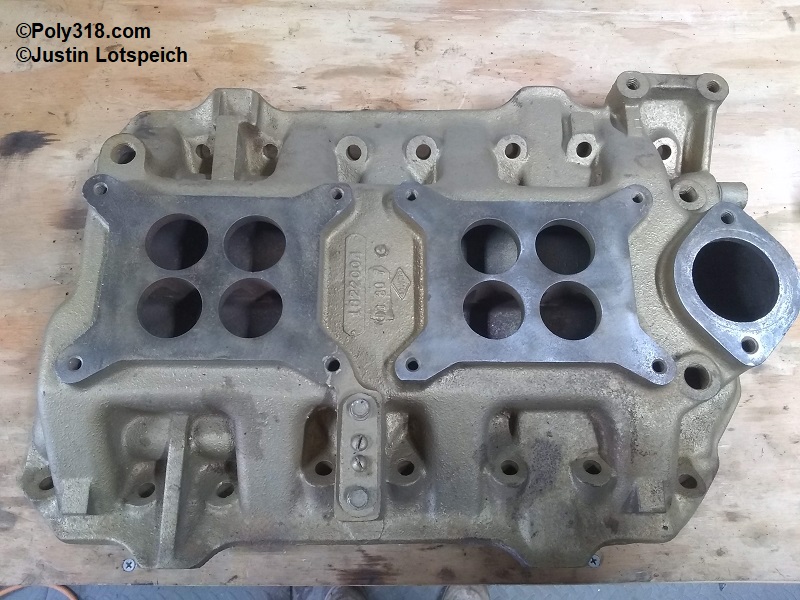

1822004 – Factory iron dual-plane 2 x 4 barrel “Dual Fury V-800”:

- The best iron factory performance intake manifold originally offered on 1957 – 1958 “Dual Fury V-800” packages. Excellent balance of performance and streetability when paired with proper carburetors, camshaft, etc. For all-out race, the Weiand WPD4D will outperform this intake.

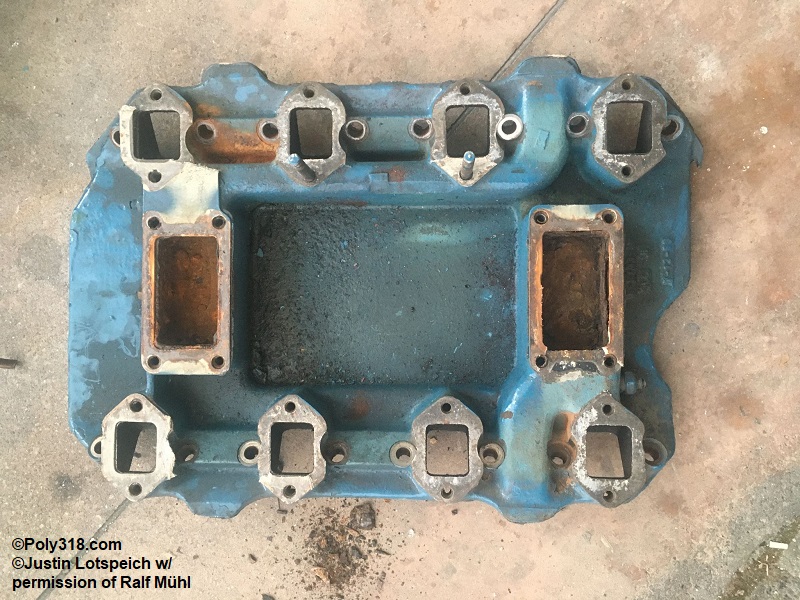

1619826, 1822004, 1859229, 2206384 – Factory iron dual-plane 4 barrel “V800 Super-Pak”:

- Known as the Super-Pak option on 1957 – 1959 engines.

- Used from 1956 – 1962 on vehicles and 1959 – 1967 on marine.

- Excellent street/strip intake for performance throughout the rpm range. Superior to the Weiand 7503 for street use.

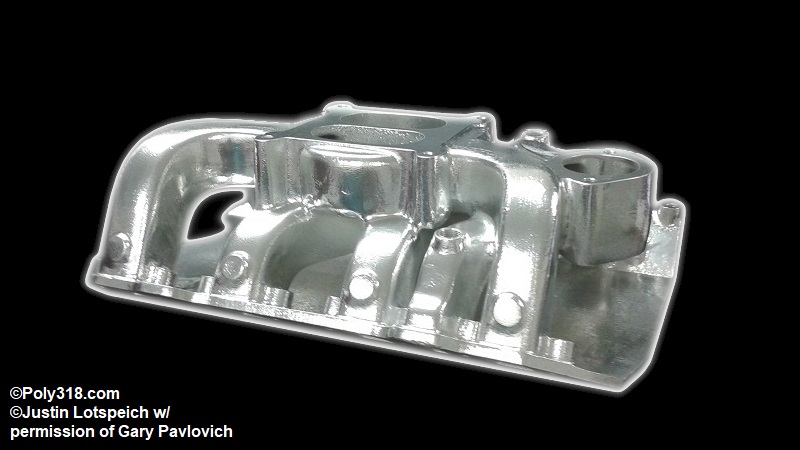

1630944, 1859228, 2206383 – Factory iron dual-plane 2 barrel (1956 -1966):

- Excellent torque and throttle response for street use. Equipped with a Trans Dapt 2040 adapter and a Holley 7448 or 80350 (350cfm) or 4412S (500cfm), the intake will outperform a four-barrel for street use. To take advantage of the 500 cfm carburetor, the two-barrel plenum opening needs to be enlarged. (4-barrel carb on the two-barrel intake upgrade advice credit Gary Pavlovich).

- Note: 1963 – 1966 engines were all 2-barrels except some marine and industrial applications.

- Note: All trucks came standard with two-barrels.

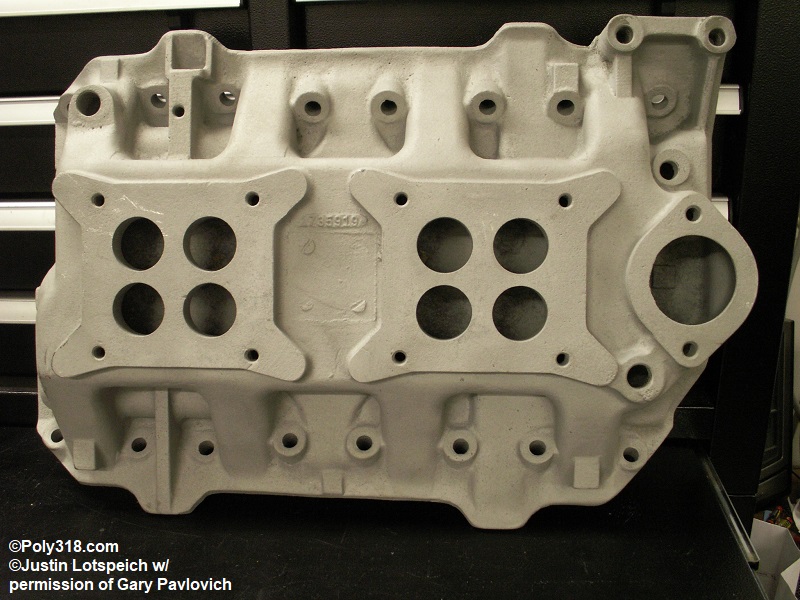

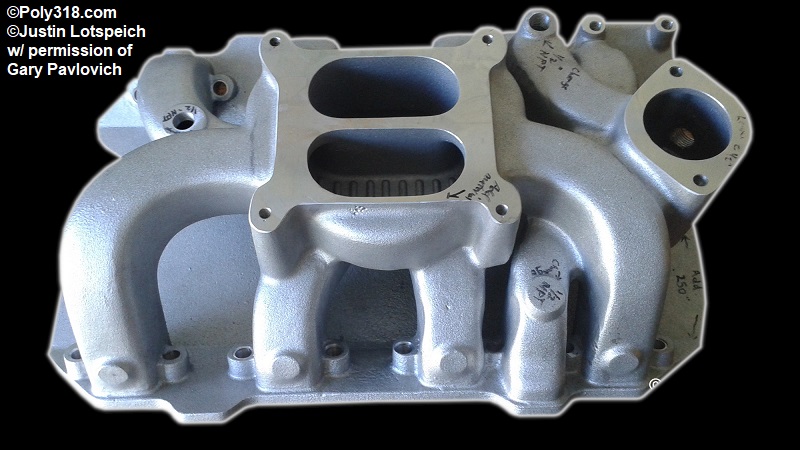

1735919 – Factory aluminum dual-plane 2×4 barrel (extremely rare):

- Offered only in 1956 through Plymouth dealerships as a performance part. The best factory performance intake manifold in design and weight. Excellent balance of performance and streetability. For all-out race, the Weiand WPD4D will outperform this intake.

- If you own one and are willing to sell it, I am interested for a period-correct build. Please contact me.

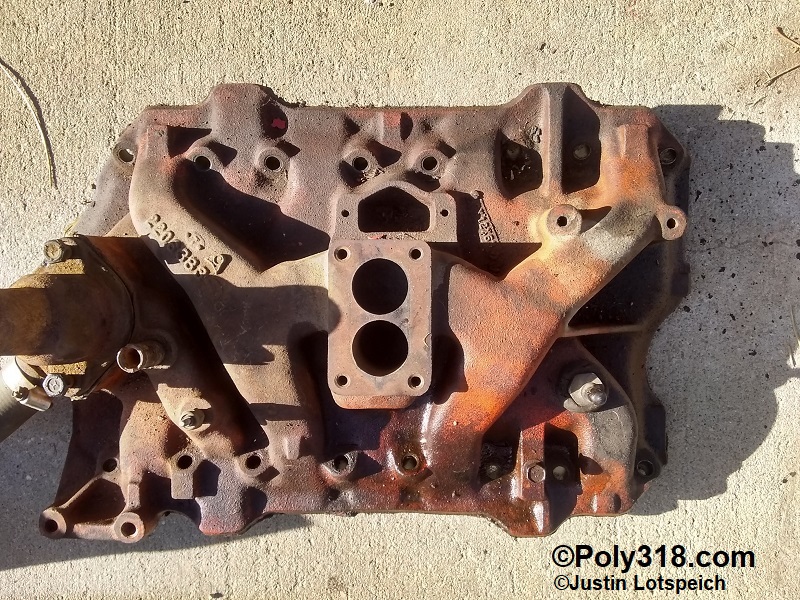

E5793M – Factory iron marine intake, dual Carter YH 1-barrel carburetors.

Aftermarket Intake Manifolds

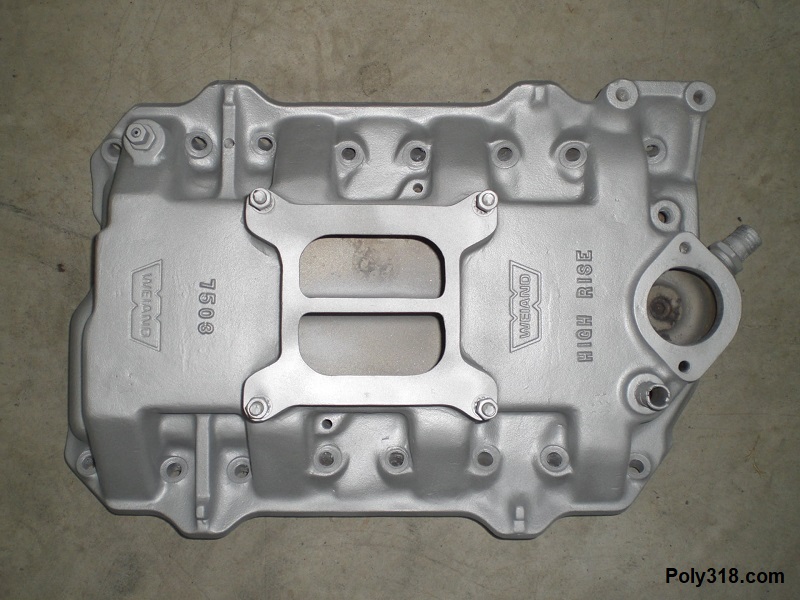

Weiand 7503 – Single-plane 4 barrel

- Ideal for an engine that will spend most of its time above 3,500 rpm prepped with a performance cam, headers, high-stall converter, and gearing of 3.55:1 or lower. Will benefit greatly from head porting. Usable on the street, but the throttle response and torque will suffer at lower rpms.

- When used on a stock engine, low-rpm performance will suffer.

Weiand WDPSQ – Early single-plane 4 barrel:

- Ideal for an engine that will spend most of its time above 3,500 rpm prepped with a performance cam, headers, high-stall converter, and gearing of 3.55:1 or lower. Will benefit greatly from head porting. Usable on the street, but the throttle response and torque will suffer at lower rpms.

- When used on a stock engine, low-rpm performance will suffer.

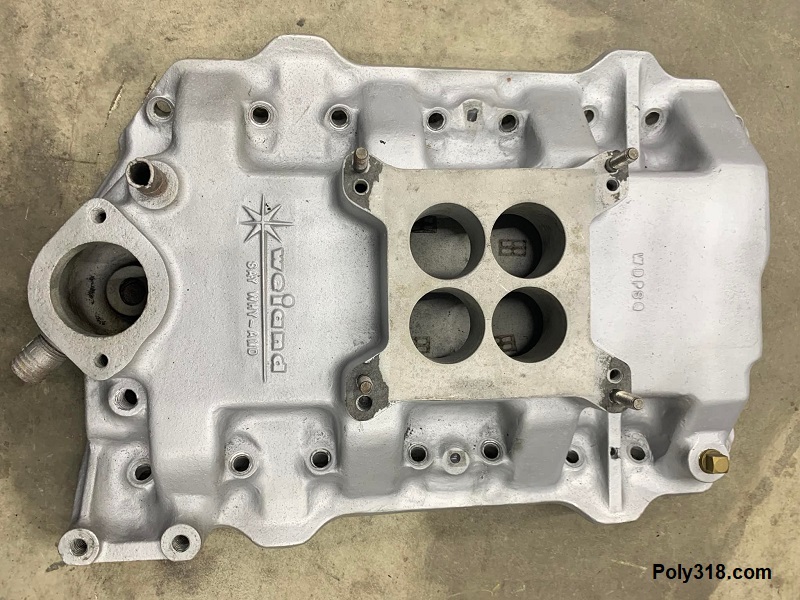

Weiand WPD4D – Single-plane 2 x 4 barrel:

- The most high-performance mass-produced intake for an A-block. Ideal on an engine that will spend most of its time above 3,500 rpm prepped with a performance cam of at least around 264/.450”, headers, high-stall converter, and gearing of 3.73:1 or lower. Will benefit greatly from head porting. Usable on the street, but the throttle response and torque will suffer at lower rpms.

- When used on a stock engine, low-rpm performance will suffer.

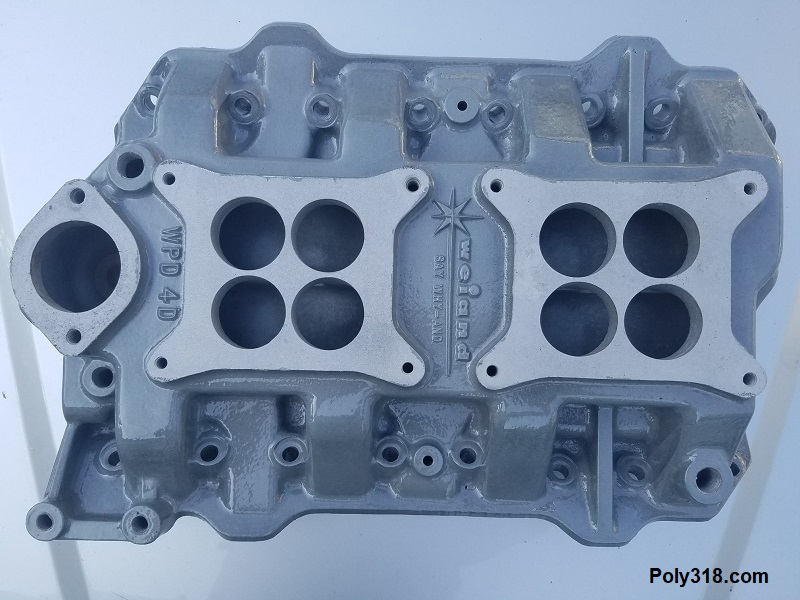

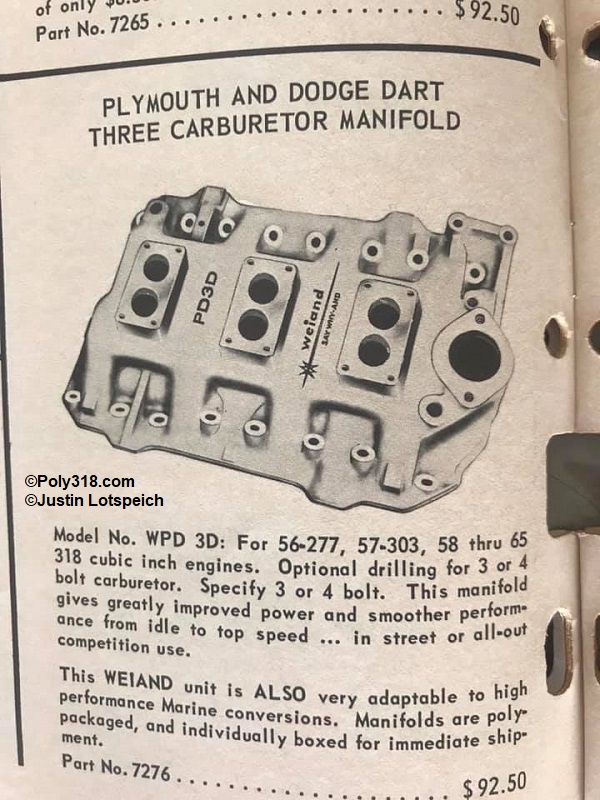

Weiand WPD3D – Single-plane 3 x 2 barrel:

- A rarer intake designed for small-base four-bolt Rochester, Carter, and Holley The one pictured has aftermarket carburetor spacers. As a single-plane design, it suffers from similar low-rpm limits as the other Weiand intakes but shares the same high-performance capabilities above 3,500 rpm. The dual-plane Edelbrock P600 is a superior intake for streetability. The photo below shows the manifold with spacers installed.

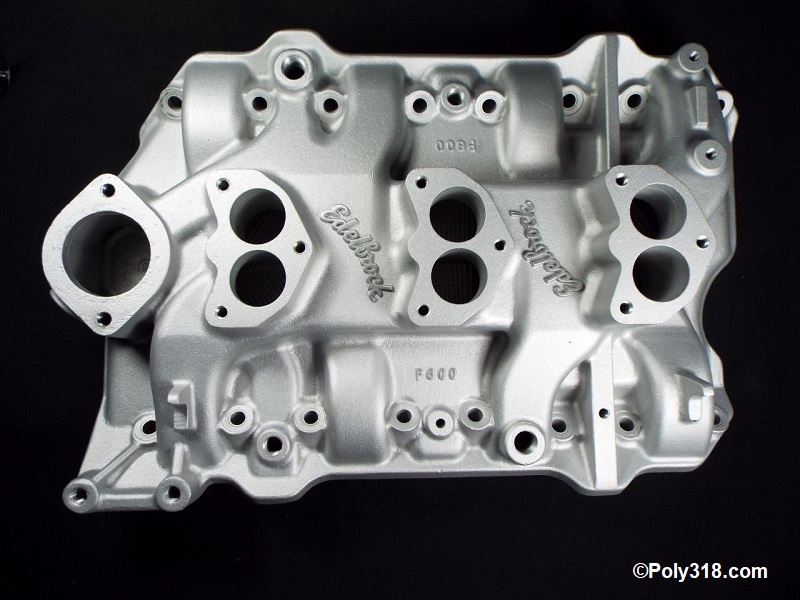

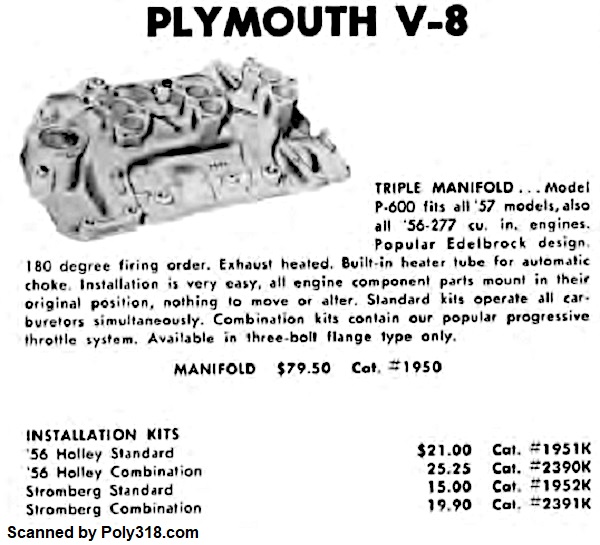

Edelbrock P600 – Dual-plane 3 x 2 barrel:

- Most were designed for early 3-bolt Stromberg 97 and Holley 94 carburetors, but they made a rare four-bolt version for small-base Rochester, Carter, and Holley. 3-bolt to 4-bolt adapters are available. The best available 3 x 2 intake for a street A-block.

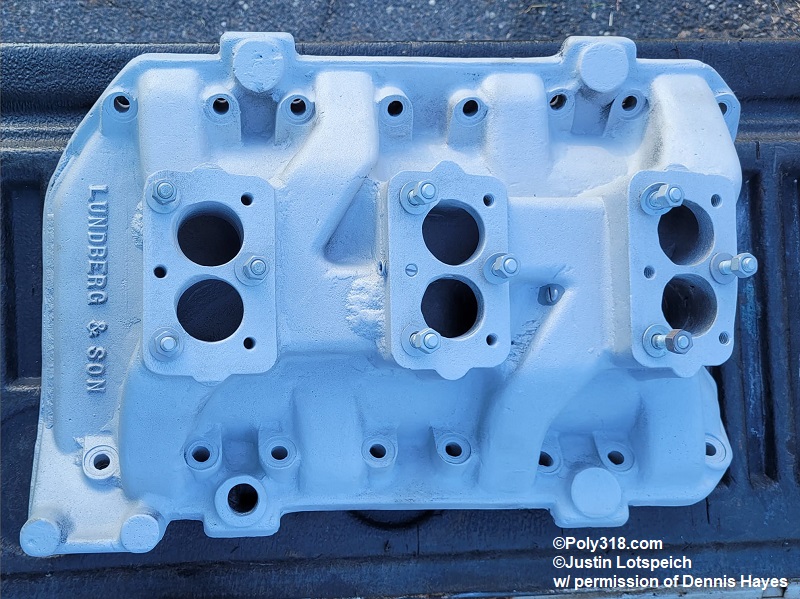

Lundberg & Sons Marine 3 x 2 barrel (extremely rare)

- An aftermarket aluminum intake manifold for marine applications designed and cast in Australia by Emil Lundberg. Note the missing thermostat crossover and water jackets. According to Emil’s grandson Grant Lundberg, only around 100 were cast in the late 1950s. My thanks to Dennis Hayes for sending me photos and information on what I had otherwise only heard of as a phantom L&S marine intake manifold.

- Interesting dual-plane design similar to the Edelbrock P600 except the center carburetor’s plenum directs one barrel toward the front plenum and the other barrel toward the rear plenum.

- Features a dual Stromberg and Rochester carburetor bolt pattern.

“Wind Tunnel” dual-plane intake:

A rare limited-production aftermarket dual plane high-rise A-block intake manifold designed by Foundry Works owner Javier Vasquez and A-bock aficionado Gary Pavlovich. Sold from approximately 2014-2019 when production ended when Javier and Gary left the project. The intake is no longer produced.

- Strong HP & TQ gains with good streetability over factory manifolds and the Weiand 7503 when equipped with the proper carburetor, cam, and other components.

- Warning: Be extremely wary of anyone requesting money for pre-ordering this intake since as of 2019 the intake is not in production and no corroborated evidence exists it will ever be produced again since the cost to produce a batch is so high compared to the very limited number of people willing to put down the cash. The original foundry contracted to produce the intakes left the project in 2019. I have received multiple emails from different people since 2020 explaining that they paid someone over $500 USD for a pre-order to collect enough money to run a batch who then never received an intake or refund within the promised time frame. Buyer beware.

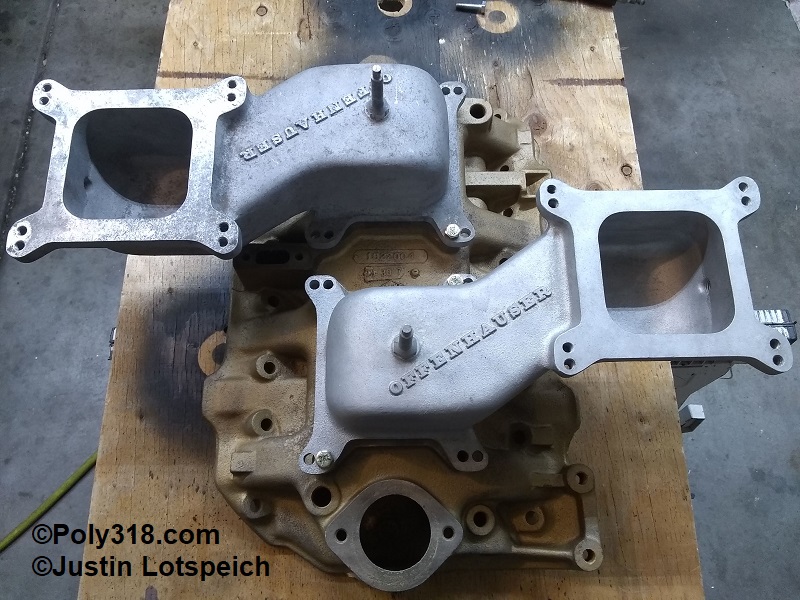

Justin’s Cross Ram Intake

While I am not the first to bolt Offenhauser 5497 cross-ram adapters onto a poly Dual Fury V800 intake, I will lay claim to designing and fabricating a cable and bell crank throttle linkage system and using unsilenced Mopar “Charger 225” air cleaners (see the finished system). While I have not measured the difference myself yet, multiple dyno results out there show a gain of 10% – 16% HP on small block Chevys and Fords, and the ported heads, larger valves, and 6,500 rpm camshaft on my Poly 390 stroker should make good use of the this induction.

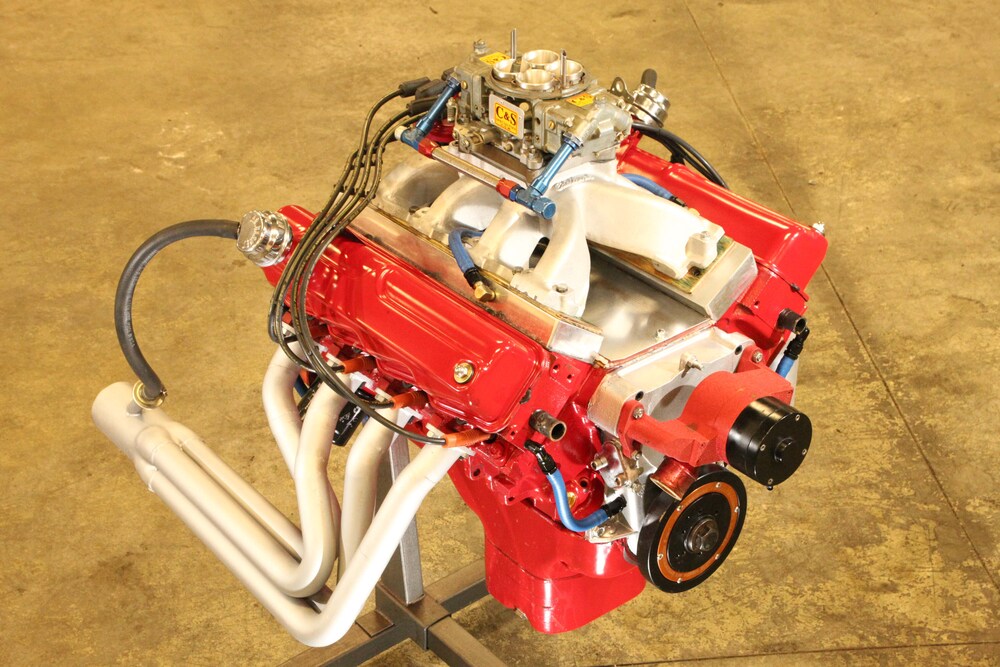

Hinkle LS1 Retrofit

- GM LS1 intake runners line up extremely closely with the A-block’s, and Buck and Clark Hinkle retrofitted an LS1 Victor Jr. single-plane manifold on their A426 build. Note that the Hinkle engine was built for the sole purpose of pulling dyno runs in a competition, evident in the valley pan that appears to have limited perimeter fasteners and is glued in place and no coolant thermostat. To make the intake work long-term on a street car, one would need to machine adapter spacers for the intake, build a valley pan that breaks at the heads and is captured between the adapter and head like a B/RB valley pan, and build a coolant crossover with a thermostat. A race-type detached coolant crossover with incorporated thermostat might be an option. While not for the weak-willed, after all this work one would have well-flowing performance LS1 intakes to choose from, including the dual-plane Edelbrock.

Poly 318 Valve Covers

(Applicable to 277, 301, 303, 313, 318, 326, 390, 402 engines)

Poly 318 Factory Stamped Steel Valve Covers

All factory valve covers were stamped steel. 1956 – 1958 and some 1959 have three bolt holes but will interchange with all year and displacement A-blocks. Most cylinder heads have the center bolt boss drilled and threaded through end of production in 1967. Those missing the center boss or threads can be drilled and tapped for the center bolt.

Note that the spark plug separators, wire loom clamps, and other mounting brackets changed throughout the years for those needing to pay specific attention for Concours-level restorations.

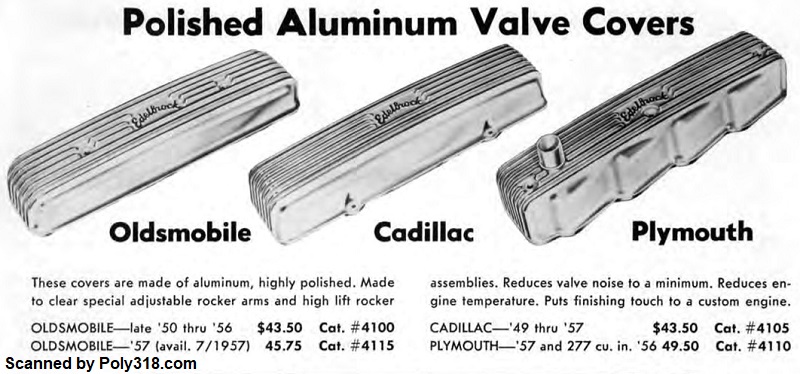

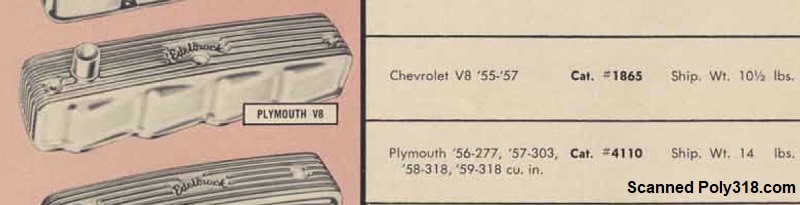

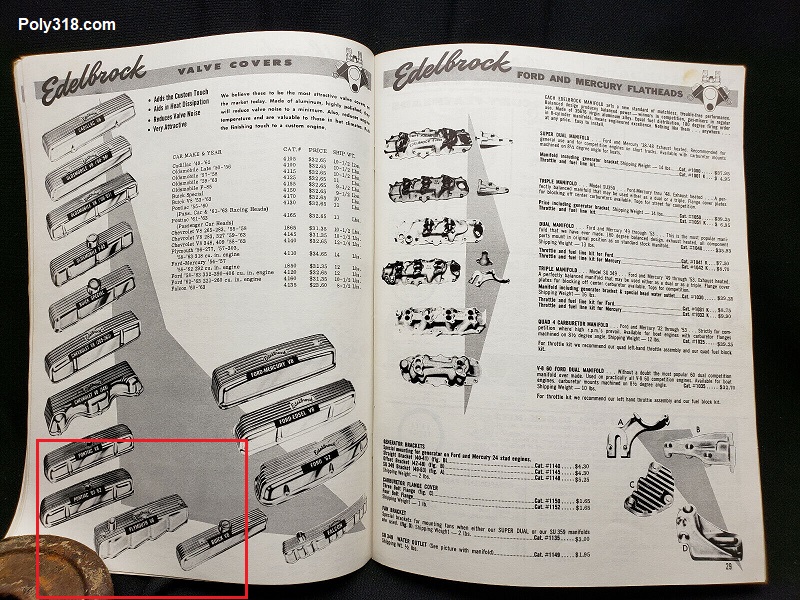

Poly 318 Aftermarket Edelbrock Finned Aluminum Valve Covers

Edelbrock model 4110 is the only vintage source for aftermarket finned aluminum valve covers, which I picture from my collection. The earliest published advertisements I have found are from the 1957 Edelbrock catalog (Figure 1a). I do not find the listing in the 1956 Edelbrock catalog or featured in any of the 1956 Hot Rod magazine advertisement sections from my collection even though the rest of the Edelbrock valve cover offerings are featured. The valve covers continued to appear in Edelbrock’s catalog with an example from 1959 (Figure 1b). I found the valve covers advertised in a 1963 Hot Rod magazine (Figure 1c) and in a 1964 Vic Hubbard Speed and Marine catalog (Figure 1d). The 1965 Edelbrock catalog no longer features the valve covers, although they were likely available through distributors and possibly directly from Edelbrock depending on available stock. I spoke with Edelbrock’s sales department (now owned by Industrial Opportunity Partners private equity group), and they supposedly still have the mold for the valve cover but require a serious number of pre-orders that comes out to about $700/set to consider producing a run. The valve covers aren’t able to be legally produced by another foundry outside of Edelbrock unless the “Edelbrock” script is removed due to copyright.

If you own a set and are willing to sell, I am interested for a period-correct build. Please contact me.

Poly 318 Aftermarket Fountain Australia Finned Aluminum Valve Covers

The only current (2023) aftermarket valve covers available produced in quantity are those made by Fountain of Australia. They come rough-cast and require sanding and polishing if desired.

Warning: Aside from Fountain’s Australian-made valve covers, be extremely wary of anyone or company requesting money for pre-ordering “USA-made” finned aluminum valve covers since no corroborated evidence exists that a USA foundry or retailer produces them as of 2019, and the cost to produce a batch is high compared to the very limited number of people willing to put down the cash. The original foundry contracted to produce USA versions stopped production in 2019. I have received multiple emails from different people since 2020 explaining that they paid someone over $500 USD for a pre-order to collect enough money to run a batch who then never received the valve covers or a refund within the promised time frame. Buyer beware.