Poly 318 Exhaust Manifolds and Headers

(Applicable to 277, 301, 303, 313, 318, 326, 390, 402 engines)

Introduction

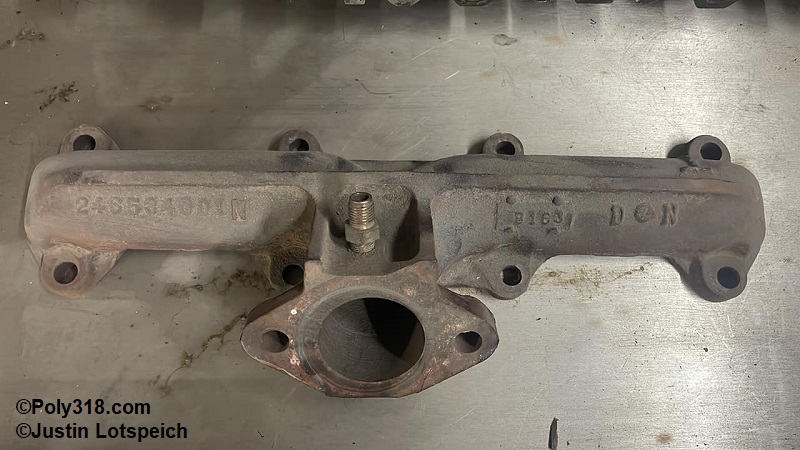

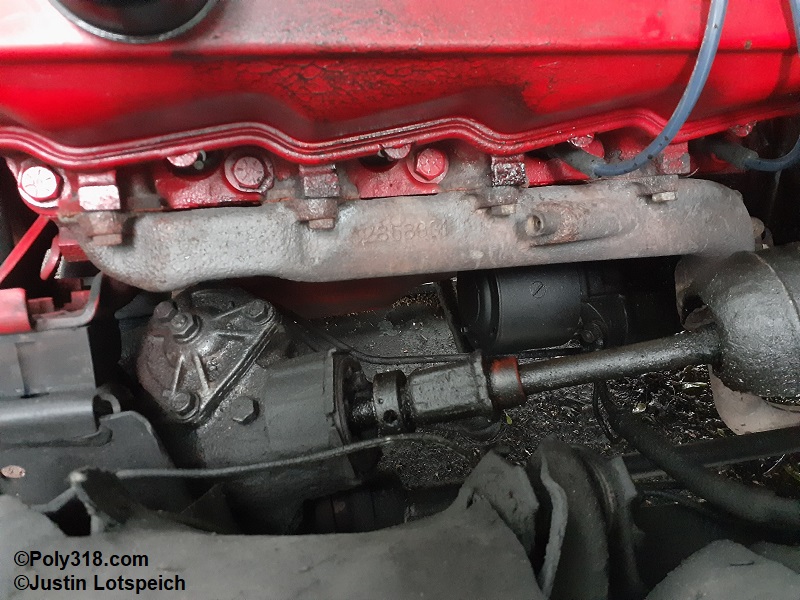

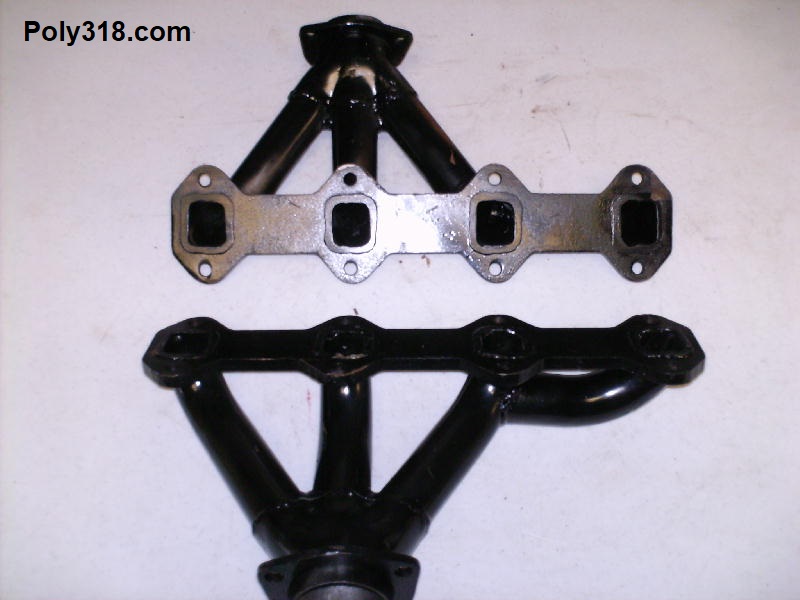

Factory vehicle exhaust manifolds, factory Marine exhaust manifolds, and aftermarket headers are available for the poly A-block, although bolt-on header options are limited to one company as of writing this article. However, I detail below multiple header options. From the factory, A-blocks came with two types of cast iron exhaust manifolds: a center dump and a rear-exit log (Figures 1 – 3). The casting designs vary depending on the vehicle and year; for example, early generator vehicles included a generator bracket cast into the manifold, and some export engines had a choke hot-air port on top of the left log exhaust manifold. The cylinder head exhaust ports are spaced evenly, so manifolds can be used on either side and even flipped upside down for turbo configurations. In general, cars took a log manifold on the left and center dump on the right, while trucks took center dumps on both sides with the left manifold lacking the heat-riser valve. I have found two Marine exhaust manifolds detailed in the last section of this page.

Factory Exhaust Manifolds

Here is a list of exhaust manifold casting numbers and their descriptions that I have compiled, although there may be other castings I haven’t come across yet.

1945095 – Center dump w/out generator bracket (1956 – 1961 or so)

1945094 – Center dump w/generator bracket (1956 – 1961 or so)

2129197 – Center dump w/out generator bracket (about 1962 – 1966)

2268189 – Left log rear dump with narrower flat front (likely 1956 – 1961)

2465840 – Right truck center dump w/out heat riser and w/ cast support flange (about 1962 – 1966 trucks)

2532415 – Left log rear dump with wider flat front (1962 – 1966)

2858331 – Left log rear dump with carburetor choke hot-air port (1962+ Canadian, info courtesy Brian Woodard)

Performance Tube Headers

Bolt-on Options

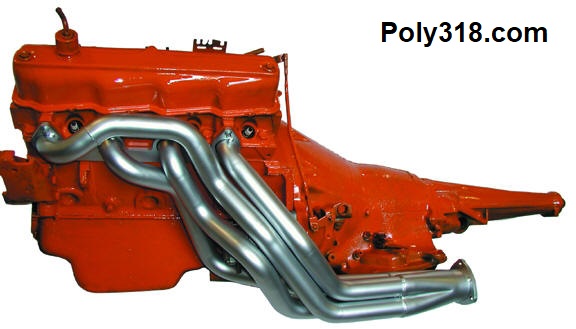

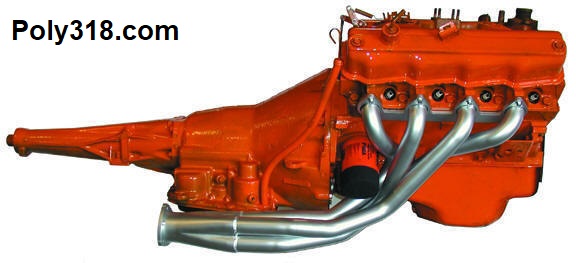

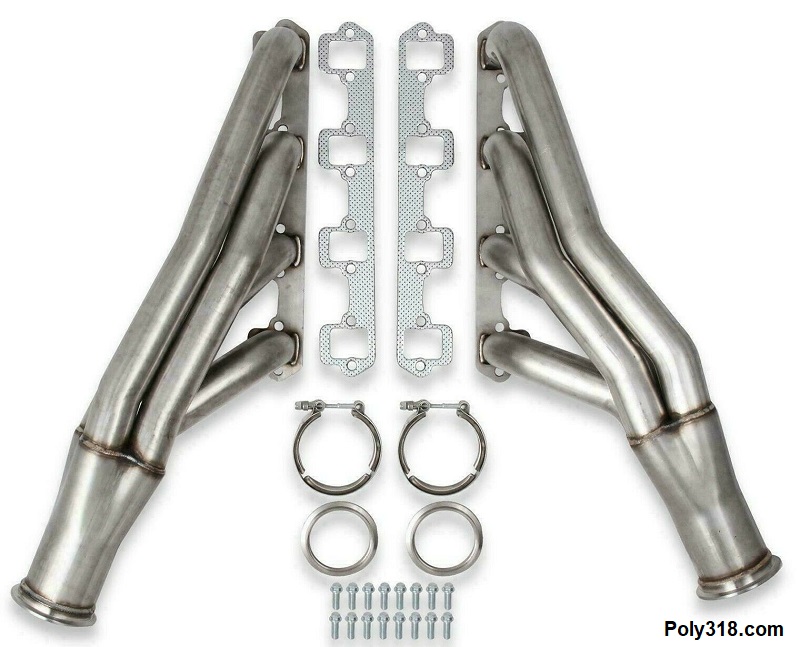

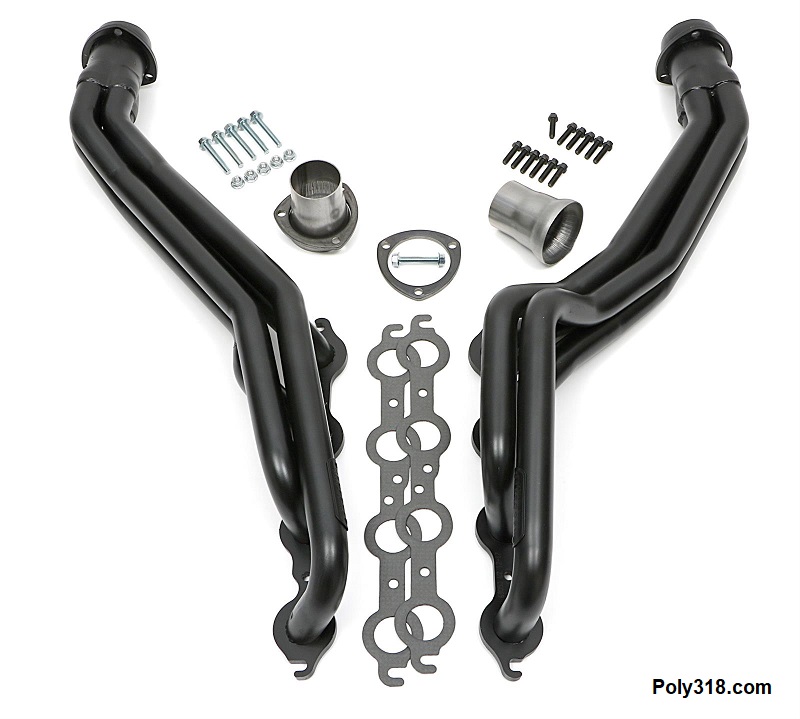

As of writing this article (2021), the only aftermarket headers available as direct bolt-ons are from TTI Performance Exhaust and Headers (Figure 4 and 5). They are full-length headers available for 1962 – 1967 B body and 1965 – 1967 C body. They are quality pieces but are limited in fitment outside these year and body ranges.

Options Requiring Modification

Luckily for those with fabrication skills or willing to pay a welder, some non-A-block exhaust ports align closely with the A-block and can be made to work by cutting off the flange, reworking the tubing opening, and welding on an A-block flange, like I did for the right side of my 1956 Dodge build (Figures 6 – 7). Another option is to build headers out of a weld-up kit, which I did for the left side of the 1956 Dodge (Figures 8 – 9). Flanges can be cut out of 3/8″ mild steel plate using the A-block gasket as a template or purchased through Hells Gate Hot Rods. Another option that works on paper but often presents fitment issues is an adapter plate that bolt to the head that are then drilled and tapped for the non-A-block header bolts; while the idea sounds good and will work in some configurations with less restrictions such as trucks, the additional spacing out of the adapter system presents clearance issues in many cars since the adapters push the headers out and down toward the inner fenders, steering components, frame rails, etc. In the end, it will take researching header photos, scrutinizing dimensions, and eventually physically trying to fit the headers. If all else fails, build-your-own header kits are available.For those wanting to do a little fabrication, I have researched and tried the options detailed below.

Ford 289, 302, and 351 Windsor and 351 Cleveland

The best bet for A-block headers is the Ford 289, 302, 351W, and 351C since tubes are dead on the A-block 4-1/2″ center to center port configuration, are rectangular ports, have a wide range of configurations available for many Ford vehicles, come in 1-1/2″ – 1-7/8″ primary tubes, and some can be inexpensive. However, from my research 289 – 351 Windsor headers are limited to 1-1/2″ and 1-5/8″ primary tubes below the $800 range. 351 Cleveland headers have very limited options at 1-3/4″ and 1-7/8″ for under $300. For example, when I began researching and purchasing headers to trial fit in my 1956 Dodge coupe build, I quickly found a lack of 1-3/4″ headers for the Windsor family and settled on a pair of Flowtech 12118 full-length headers made for a 1970’s Gran Torino 351C (Figure 10). The right header fit relatively well, but the left header ended up having serious clearance issues with the steering and stater motor that modification wouldn’t overcome. I moved on to a pair of Flowtech 12164 mid-length headers that would likely fit many configurations well but ran into the Dakota control arms (Figure 11). The Hedman 886600 shorties are another option, which I did not try) but only come in 1-5/8″ (Figure 12).

Chevrolet 1997 onward LS

Chevy LS (Gen III and IV small block) headers would be my second choice since they have some variety, although not as much as the Ford headers and often more expensive. A benefit of the LS headers is that they make them for LS swaps into older GM vehicles, so they are available for setups with tight clearances. A downside is that they are round ports (the A-block has rectangular), and they are limited in their 1-3/4″ and 1-7/8″ primary tubing with far more options at 1-1/2″ and 1-5/8″. For example, the Hedman 69050 (Figure 13) would likely be a good fit for my 1956 Dodge build, but they only make them in 1-5/8″ which will kill power for my particular A390 stroker. Figure 14 is a shorty version. Note that I have personally tried fitting shortly S10 “swap” headers (Figure 15) onto an A-block, and the collectors run into the block and bellhousing badly and are unusable.

Gen I Hemi 331, 354, 392 and Gen III Hemi

Lastly, Gen I Hemi and Gen III headers can work, but most are block-huggers and lake-style and tend to me more expensive than comparable Ford and Chevy versions (Figure 16). Gen III 5.7 Hemi headers are the same port spacing as well but are limited in styles.

Vintage Headers

As a historical note, Spitfire Headers made A-block headers (Figure 17), and sets come up for sale once in a very long while. However, the semi-“Y” design stuffs cylinder 1 into cylinder 3 and 2 into 4 with a sharp 90 degree turn to deal with clearances in cars, killing potential performance. The headers are a lot better than factory logs and a little better than factory center dumps. Considering their limitation and how rarely they come up for sale, I would rather focus on adapting a set of non-A-block headers or going with TTI.

Poly 318 Marine Exhaust Manifold: Fury 210, Fury 235, M318A, Sea V

I have only been able to locate or have been sent photos of two types of A-block marine exhaust manifold. The most common appears to be an end-outlet version (Figure 18) that I have confirmed on Fury 210, Chrysler M318A, and Chrysler Sea V. Another variant with a side outlet (Figure 19) exists, but I have only confirmed it on a Fury 210. I surmise that these exhaust manifolds were not specific to a particular engine model but instead depended on the craft the engine was installed in for clearance/routing purposes. Marine A-block images are hard to come by, so please email me if you have photos to share.