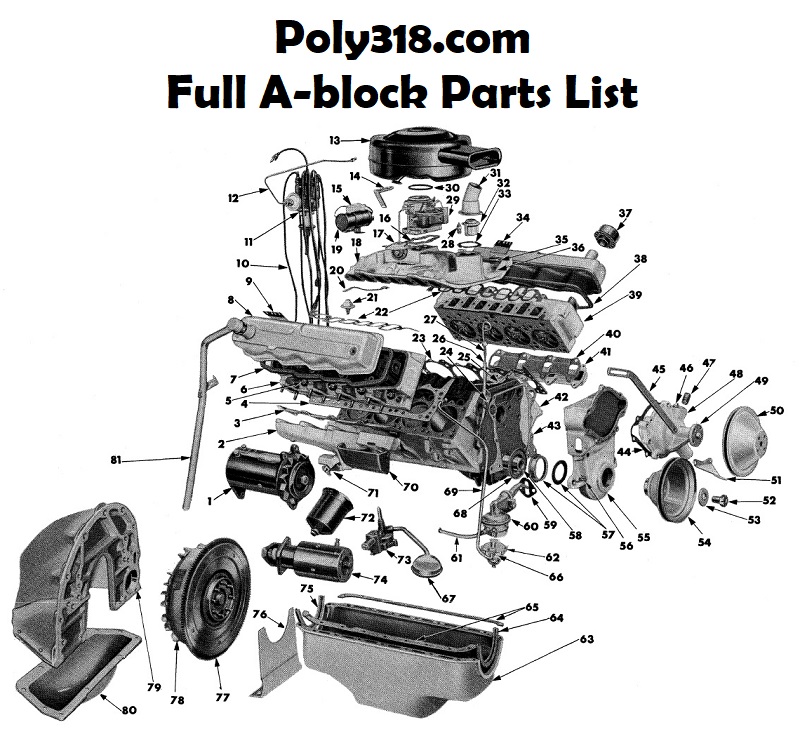

Poly 318 Engine Parts List

(Applicable to 277, 301, 303, 313, 318, 326, 390, 402 engines)

I have compiled a thorough parts list for the poly 277, 301, 303, 313, 318, and 326 using available brands I use and trust. I am not sponsored by any of these companies. For A-block and LA interchange information, see the parts interchangeable page. These part numbers should cross-reference to different brands, and I provide detailed notes. Many of these parts can be found at Summit Racing, JEGS, Speedway Motors, Rock Auto, Napa Auto Parts, and other retailers.

| Component | Engine for Lookup | Part Numbers and Notes |

|---|---|---|

| Assembly Lubricant, Engine, All but Cam Lobe and Lifter Foot | Red Line 80312 | I use this assembly lube for all internal engine components except the camshaft lobe and lifter foot. |

| Assembly Lubricant, Engine, Cam Lobe and Lifter Foot | Driven 00732 or 00738 | I use this assembly lube on the camshaft lobes and lifter feet. Warning: Do not use on the sides of the lifter bodies since it is too tacky and stops the lifters from immediately spinning upon startup. |

| Bearings, Camshaft, Stock and Performance | A-block and LA273/318/340/360 | I prefer Clevite SH875S. WARNING: 1979 onward LA/Magnum camshaft bearings changed in design and do not interchange with 1956 – 1978 A/LA. |

| Bearings, Connecting Rod, Stock | A-block and LA273/318/340/360 | I prefer Clevite trimetal P-Series CB481P8 |

| Bearings, Connecting Rod, Performance | A-block and LA273/318/340/360 | I prefer Clevite trimetal H-Series CB481H (standard fillets) or CB481HN (enlarged fillets) WARNING: Aftermarket forged crankshafts usually have larger fillets and require narrow bearings, such as the HN designation, Consult the crank manufacturer and verify during mock-up. |

| Bearings, Main, Stock | A-block and LA273/318/340 | I prefer Clevite trimetal P-Series MS1344P Full Groove |

| Bearings, Main, Performance | A-block and LA273/318/340 | I prefer Clevite trimetal H Series MS540H. WARNING: Aftermarket forged crankshafts usually have larger fillets and require narrow bearings, such as the N designation in MS540HN. Consult the crank manufacturer and verify during mock-up. Important Differences in Main Bearings: You may run across a discussion of a change in the thrust bearing thrust-wall height and how putting a 1974 onward thrust bearing in a pre-1974 block may cause binding if the rabbit in the block webbing and/or main cap is not machined tall enough to where the bearings thrust wall bottoms out and the bearing is held off of the webbing/cap. This situations will cause the crank to bind. However, A-block builders may disregard this concern. The thrust bearing change was only on the LA360, which indeed uses a different part number for 1971 – 1973 and 1974 onward. I’ve reviewed Clevite and other manufacturers’ parts catalogs, and they all show the A-block 277/301/303/313/318/326 and LA273/318/340 use the same bearing from 1956 – 2000 with a thrust bearing OD of 3.50″ give or take a few thousands depending on bearing manufacturer. |

| Camshaft | A-block | Major aftermarket part retailers no longer carry or can source A-block camshafts. Note that the wedge LA camshafts are completely different from the canted-valve A-block. The A-block has a lobe configuration starting at cylinder one running back of exhaust/intake/exhaust/intake/etc.; the LA has a configuration of exhaust/intake/intake/exhaust/etc. Cast blanks are no longer produced and are getting difficult to source. The cheapest option if the used camshaft is a good core is to have it reground. See the page on camshafts for recommended cam grinders and specifications. Another option is to have a new camshaft machined from billet, although this is a more expensive option for flat-tappet lifters and argues for converting to roller lifters. See the above camshaft page for details about using a billet LA blank and who builds roller camshafts for the A-block. Note that a reground camshaft may require longer pushrods, which should be checked during mock-up. |

| Cylinder Head Bolts | A-block See Notes | No engine bolt manufacturer I know of produces a 6.5″ long 1/2″-13 cylinder head bolt, which is what the A-block uses for the center bolts and differs from LA bolts. The shorter outer bolts are available through ARP. The factory bolts are extremely high quality and can be reused for both OEM and performance builds up to 500 HP/TQ. Above that and for forced induction applications, I recommend the ARP studs listed next. For what it’s worth, the factory bolts are 160,000 psi tensile strength, which is the rating for Grade 8. While head bolts are produced with extremely tight tolerances, a reduced shank, and a shoulder on the head, a quality Grade 8 bolt is a suitable option even though unorthodox. I would prefer to reuse the factory bolts, but as they become difficult to find we might end up being left with common Grade 8 bolts as the only option besides studs. A Grade 8 washer must be used since the bolt does not have a built-in shoulder, so the ideal length would be 6.625″ – 6.75″ to account for the washer thickness. |

| Cylinder Head Studs | See Notes | ARP AR8.0 or AR8.5 for the center ARP AR4.060 for the outer ARP Washers 2008534 ARP Nuts 2008637 |

| Cylinder Head Dowels | A-block and LA | 0.390″ diameter x 1/2″ – 3/4″ long |

| Dipstick Tube, Oil | All A-block, LA with Modification. See Notes. | Trans-Dapt 9224 Note: The exact A-block dipstick tube is not reproduced, but an LA tube and dipstick can be used by bending for clearance as necessary and by sanding down the diameter of the stub that presses into the block. |

| Distributor | All LA and some Magnum 318/360 | Recommended: FireCore distributor FBO distributor See the ignition system page for selection and tuning. WARNING: Cheap units, such as Pertronix and Proform, are built with inferior, cheap imported components and often have reliability and performance issues for both street and racing optimum performance and reliability including erratic/bouncing timing and cutting out. These issues are often attributed to the shaft being bent, the cam being machined out of round, and/or the electronics. 2000 – 2013 Mopar Performance distributors with the miniaturized Accel GM HEI internals are also prone to erratic timing and should be avoided. |

| Distributor Intermediate Drive Shaft, Stock, Iron Gear | All LA | Melling IS72 Sealed Power 224-6166 Mopar P3690715 |

| Distributor Intermediate Drive Shaft Gear, Nickel/Bronze Allow | All LA | Comp Cams 420 Howards Cams 94415 Crower 76010 Mopar (Shaft and Gear) P3690874 Note: A nickel/bronze alloy gear is extraordinarily rarely needed for an A-block camshaft since most are flat-tappet. These camshafts and the iron intermediate drive shaft gears play well since they are both harder than a roller camshaft. No softer-alloy roller camshafts are readily available outside of full-on custom jobs that may require a softer intermediate driveshaft gear. If you choose to run a nickel/bronze alloy gear on a flat-tappet camshaft, beware that the first gear you install may wear out sooner than expected as it hones the harder camshaft gear, but the second gear you install should wear less since the camshaft gear has been honed smoother. |

| Distributor Intermediate Shaft Bushing | LA273/318/340/360 B/RB | Melling M63030B Mopar P1737725 |

| Exhaust Manifold Studs and Bolts | Generic, See Notes. | 3/8″-16 into head x 2″ long for cast-iron manifolds (often 3/8″-24 for nut side). See the manifold installation tech article. The bottom row goes through to the coolant jacket and must use studs with sealant such as RectorSeal T Plus 2 (see the installation guide). The top row are blind bosses and can use either studs or bolts. Check ebay for best prices on bulk studs. ARP 100-1414 or 400-1414 are the appropriate studs, although expensive. |

| Flexplate and Flywheel | 1962 onward A/LA273/318/340 Internal Balance Only See Notes | WARNING: Cast-crank LA340 and 360 are externally balanced and may have weighted flexplate/flywheel. Using a weighted flexplate/flywheel on the internally balanced A-block will throw it out of balance. |

| Freeze Plugs 1956 – 1961 | A-block | Melling MEP14B (brass dish) Sealed Power 3811014 (steel dish) Note: These kits do not include the oil bypass plug. See the oil bypass tech article for repair details. |

| Freeze Plugs 1962 – 1967 | LA273/318/340/360 | Melling MPE-613BR or Sealed Power 3818010 (brass cup with cam plug) Napa 567014 (brass cup without cam plug) |

| Fuel Pump, Mechanical, Stock Flow/PSI | A-block and LA | Carter M6866: 1/4″ NPT ports, 25 GPH, approximate rating of 7 PSI, unregulated. |

| Fuel Pump, Mechanical, Performance | A-block and LA | Edelbrock 1720: 3/8″ NPT ports, 110 GPH, 6 PSI, internally regulated, adjustable base. Note: Entire fuel system from the tank pickup to the pump must be sized to at least 3/8″ to take advantage of the pump’s volume ability. If the system will remain 5/16″ before the pump, use a 1/4″ NPT port pump. See my page on fuel system modifications for ideas about sizing up to 3/8″. |

| Gasket, Full Set | A-block | FelPro FS7734PT2 Best Gasket RS579G |

| Gasket, Air Cleaner | A-block and LA | 4-barrel WCFB and AFB (4.20″ I.D.): Dana Victor Reinz 711381400 (fiber) 4-barrel AVS/Holley (5.10″ I.D.): FelPro 60038 (fiber) Dana Victor Reinz 711372700 (fiber) 2-barrel (2.625″ I.D.): FelPro 5198 (fiber) Dana Victor Reinz 711385400 (cork) |

| Gasket, Cylinder Head | A-block | FelPro 7734PT Manufactured: 0.037 Crushed Thickness: 0.0333 |

| Gasket, Exhaust Collector | A-block | FelPro 9045. Confirm diameter per vehicle’s exhaust system. |

| Gasket, Exhaust Manifold | A-block | FelPro MS9342B. See the manifold installation tech article. |

| Gasket, Fuel Pump | A-block | FelPro 6579 |

| Gasket, Intake Manifold, Fiber | A-block | Best Gasket 18019. Superior to factory steel type. See the manifold installation tech article. |

| Gasket, Intake Manifold, Steel | A-block | FelPro MS9344SH. See the manifold installation tech article. WARNING: Steel intake gaskets are known to leak depending on the trueness of the head and intake mating surfaces. I highly recommend using the fiber gasket. |

| Gasket, Oil Filter, Canister Type | A-block, Gen I Hemi/Hemi-block Poly | FelPro 70522 Fiber Type WARNING: Do not use the rubber gasket, for they easily squeeze out and leak. |

| Gasket, Oil Filter Adapter to Block | A-block and LA | FelPro 70522 WARNING: Don’t use the rubber gasket since they are prone to pushing out and leaking. |

| Gasket, Oil Pan | A-block and LA 273/318/340 | FelPro OS6566C2 or 1806 |

| Gasket, Thermostat Housing | Gen I Hemi/Hemi-block Poly, A-block, LA | FelPro 35063 |

| Gasket, Timing cover | A-block and LA | FelPro TCS65631 or TCS45284 |

| Gasket, Valve Cover | A-block | FelPro VS11828R or VS11828C |

| Gaskets, All Others | LA273/318/340 | |

| Harmonic Damper | A-block, LA273/318/340 Internally Balanced with Modification | The A-block never used a harmonic balancer since they are internally balanced. The A-block damper with the timing mark clocked on the right is no longer produced. LA273/313/340 internally balanced dampers fit but have the timing mark clocked on the left: Stock: Dorman 594021 or similar Performance SFI: Trick Flow 19010 or similar to use the LA damper, you must find cylinder #1 true top-dead center on the compression stroke and remark the hamper timing line to align with the A-block pointer. |

| Harmonic Damper Seal Repair Sleeve | A-block and LA | FelPro 16201 or Pioneer HB2124 |

| Heater Bypass Hose, Intake Manifold | A-block and LA | DAYCO 70476 for 3/4″ Nipple |

| Lifters Warning | Read Notes First | Topline Automotive as of 2020 is supposedly one of two lifter manufacturer that casts the lifter bodies and produces the internal components in the USA. They have their own brand called “Hylift Johnson,” but be forewarned that as of 2020 the finish quality of the Hylift Johnson brand can be terrible with deep gouges/nicks in the lifter foot and sides, which I discuss in the next paragraph. Also be forewarned that there is a competitor named “Johnson Lifters” that advertises their lifters as being made in the USA, but my understanding from speaking to different retailers and to Top Line Automotive is that “Johnson Lifters” has the bodies cast outside the USA with enough machining and assembly in the USA to legally claim “Made in USA” even though the bodies are imported. There have been issues with the imported metallurgy that may result in the lifter face deteriorating and flattening the camshaft lobes, especially when an appropriate oil with ZDDP additives is not used; however, recent imported lifters show quality metallurgy and machining, so I hope the days of bad lifters are behind us. My recommendation is to modify the lifter bores for direct cam lobe oiling (see my oil modification page for details of this modification) and run a quality engine oil with ZDDP (I prefer Valvoline VR1 oil). In my and other people’s experience, Hughes Engines Hylift Johnson line of lifters have shoddy and unacceptable face finishes, especially for the price. Hughes Engine’s customer service in my experience dealing with damaged lifters has been terrible, and I will never use the company again. Sets I and at least two others I know purchased through Hughes Engines (lifter 5003) have deep gouges in the face right out of the box that a mechanic’s pick catches on. These gouges are common during the manufacturing process as the lifter bodies crash against each other, but a precision crowned finish on the lifters before they are assembled should grind off all gouges and leave a clean finish. Gouges in new lifters suggests poor craftsmanship and quality control, and the gouges may result in uneven wear and damage to the lifter and camshaft should the lobe edge hit a high spot caused by the gouges and stop spinning. The lifters I recommend below have excellent metallurgy and finish and use the Top Line Hylift Johnson USA-cast bodies but with a superior finish and internal components. |

| Lifters, Mechanical, Flat-tappet, Stock Replacement | A-block, See Notes Regarding LA. | Melling JB2084 or Sealed Power AT2084 Note: I have not been able to confirm through Melling, Sealed Power, and Topline, but the Melling and Sealed Power solid flat-tappet lifter bodies are identical to Topline Hylift Johnson lifters. However, these direct replacement lifters often cost as much as a set of premium LA lifters, so I recommend using LA lifters from the brands below with custom-length pushrods. |

| Lifters, Mechanical, Flat-tappet, Performance | LA | Lunati 70937 (my preference); Crower 66945; Comp Cams 2901 (with EDM direct-lobe oiling holes) Note: The premium LA mechanical flat-tappet lifters require custom-length pushrods since the lifters are taller than A-block lifter. |

| Lifters, Hydraulic, Flat-tappet, Stock Replacement | A-block, See Notes Regarding LA. | Melling JB879 or Sealed Power HT879 Note: Quality stock A-block replacement lifters often cost more than premium LA lifters, so I don’t use them anymore and instead use premium LA lifters and order custom-length pushrods. |

| Lifters, Hydraulic, Flat-tappet, Performance | LA | Lunati “Micro-Trol” 71977 high performance (my preference); Howards “Max Effort” 91712 high performance; Roads “V-Pro Street” 2018P variable duration high performance. Note: The premium LA hydraulic flat-tappet lifters require adjustable rocker arms to set preload and custom-length pushrods since the lifters are taller than A-block lifter. |

| Lifters, Hydraulic, Roller, Performance | LA | |

| Lifters, Mechanical, Roller, Performance | LA | |

| Oil, Normal Operation for flat-tappet and roller lifters | See Notes | I run Valvoline VR1 10W30 conventional for both engine break-in and normal operation because independent tests have shown it has a far superior film strength of 103,000 psi than insanely overpriced break-in and performance oils, and its additive package does not have excessive amounts of zinc, phosphorus, and other additives that in lab tests have actually damaged metal. It has 1400 PPM zinc and 1300 PPM phosphorus, which are both maxed out for safe limits without harming the metal parts over time. Any comparable oil with above 90,000 psi film strength is appropriate for our engines. Anything below 70,000 psi should be avoided. To explain more, I get VR1 for $6/quart that outperforms Amsoil “Z Rod” at $15/quart with 95,000 psi film strength and Joe Gibbs “Driven Hot Rod” at $10/quart with 86,000 psi film strength. Both of those oils have great film strength but not as good as VR1. Both those oils also have similar amounts of zinc and phosphorus. In comparison, Lucas “Break-in” has a dangerously low 49,000 psi film strength along with dangerously high levels of 4400 PPM zinc and 2600 PPM phosphorus. The Lucas oil is a prime example of the high-ZDDP formula myth since if the myth were true the Lucas oil would have far higher film strength than VR1. WARNING: I would not use synthetic to seat new piston rings since the wear protection impacts quicker seating. |

| Oil, Rebuild Break-in | See Notes | I run Valvoline VR1 10W30 conventional oil for engine break-in because independent tests have shown it has a far superior film strength of 103,000 psi than insanely overpriced break-in and performance oils, and its additive package includes good levels of ZDDP but does not have excessive amounts that in lab tests have actually damaged metal. It has 1400 PPM zinc and 1300 PPM phosphorus, which are both maxed out for safe limits without harming the metal parts over time. WARNING: I do not use synthetic oil to seat new piston rings since the wear protection impacts seating the rings. |

| Oil Filter, Canister Type | A-block, Gen I Hemi/Hemi-block Poly | Wix 51076 |

| Oil Filter, Spin-on Type | A-block and LA | Note: Unless otherwise noted, the following filters all have 3.66″ diameter and are the same rating of 7 – 9 GPM flow, 21 micron element, and bypass pressure of 8 – 11 psi. Shortest and Narrow 3.40″ long x 2.92″ diameter (good for header clearance): Wix 51348 Extra Short: 3.37″ (16 psi bypass, which is not an issue for the A-block): Wix 51311 Very Short 3.78″: Wix 51521 Short 4.34”: Wix 51068 Standard 5.20”, 1 quart: Wix 51515 Extra Long 7”, 2 quart: Wix 51773 |

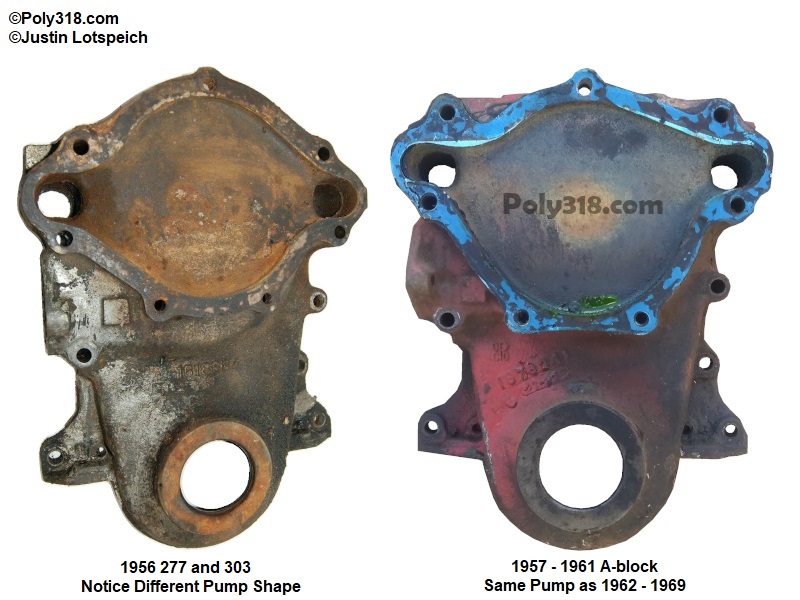

| Oil Pump, Standard Volume/PSI 1956 – 1961 | A-block | Factory part is 1618949 with a housing casting number 1618952. Aftermarket pumps are Melling M51 for 277, 301, 303 , 313, 318, 326. |

| Oil Pump Cover Seals, Melling M51, 1956 – 1961 | 1956 – 1961 A-block (e.g. 1958 Plymouth Fury A318) | Buna Nitrile (NBR) Square O-rings: 2-3/8″ ID x 1/8″ wide AS568-229 7/8″ ID x 1/8″ wide AS568-212 |

| Oil Pump, Standard Volume/PSI 1962 – 1967 | A-block and LA | Melling M72 |

| Oil Pump, Standard PSI, High Volume 1962 – 1967 | A-block and LA | M72HV Note: Extremely few performance A-blocks require a high-volume pump due to the engine’s superior oiling design. Higher pressure is better for 90% of performance builds. |

| Oil Pump, Standard Volume, High PSI 1962 – 1967 | Must Modify A-block/LA. See Notes. | No high-pressure pump is available. See my technical article on converting to high pressure. |

| Oil Pump Intermediate Drive Shaft, 1956 – 1961 | A-block | Melling IS47 (shaft only, requires gear) Note: The later A-block and LA shaft is not interchangeable. |

| Oil Pump Intermediate Drive Shaft, 1962 – 1967 | A-block and LA | Melling IS72 |

| Motor Mounts Cup and Snubber Style 1957 – 1959 Plymouth 1957 – 1959 Dodge 1959 Chrysler | A-block | OEM Numbers 1635326, 1734529, 1827449, 1828237, 1944724 all discontinued TRW 2133 Search online for NOS or reproductions by “Old Parts Source” |

| Motor Mounts Non-captured, Two Studs 1960 – 1966 | A-block and LA | 2227 – Left 2228 – Right |

| Motor Mounts Non-captured, One stud 1967 – 1972 | A-block and LA | 2250 – Left and Right |

| Motor Mounts Captured 1973 onward | A-block and LA | 2325 -Right w/ Bracket 2326 – Left w/ Bracket 2369 – Left/Right Insert Only Note: Will fit A-block engine flanges but required building or adapting the chassis mounts |

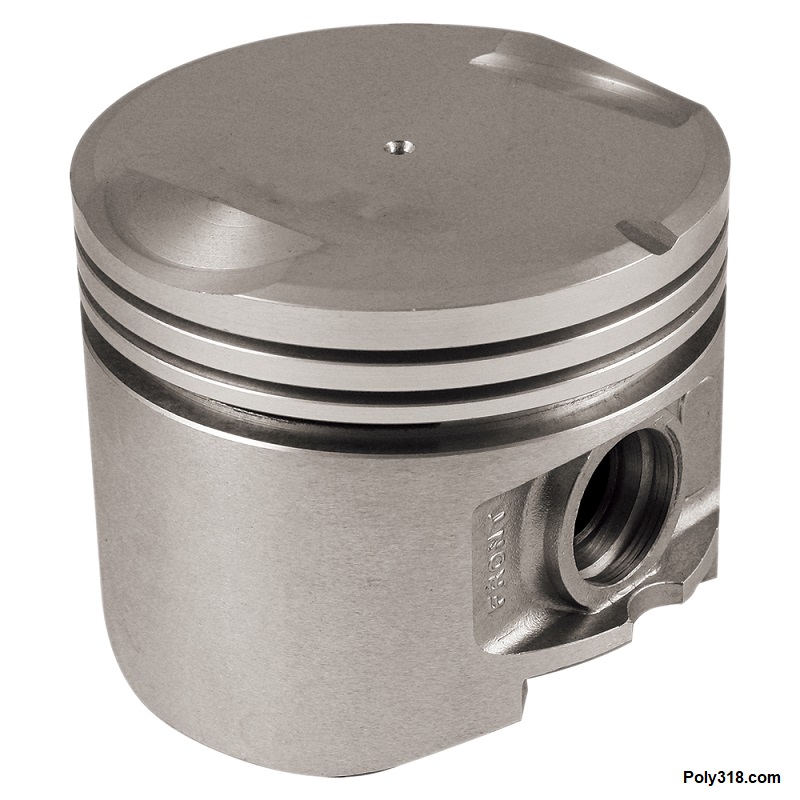

| Pistons, Cast, 318 Bore/Overbore | A-block. See Notes for LA Option. | Egge L2050 (Figure 2a). Check Ebay for best prices on these pistons. LA318: LA318 flat-top pistons without valve reliefs can be used if valve reliefs are fly-cut for the A-block valves. |

| Pistons, Cast, 340 Bore | LA340 | LA340 flat-top pistons without valve reliefs can be used if valve reliefs are fly-cut for the A-block valves. WARNING: To overbore the A-block to 4″, the block should be sonic tested to ensure minimum cylinder wall thickness. |

| Pistons, Forged, Custom | Custom. See Notes. | Race Tec/Auto Tec (California) or Ross Racing Pistons. Both manufacturers have the drawings for and have produced A-block pistons. |

| Pistons, Billet, Custom | Custom. See Notes. | Gibtec Pistons (Colorado) |

| Piston Rings | Not Specific to Engine. Match Bore and Piston Grooves. | I prefer Hastings or Total Seal. I prefer thinner 1/16″ x 1/16″ x 3/16″ for custom pistons. |

| Pulley, Crankshaft, 1956 – 1992 | A-block and LA | 1970 – 1992 and aftermarket LA dampers and pulleys have a slightly different pulley bolt pattern, so using a 1970 – 1992 pulley on a pre-1970 damper or pre-1970 pulley on a later damper requires elongating pulley holes, which will not have a negative impact on anything. |

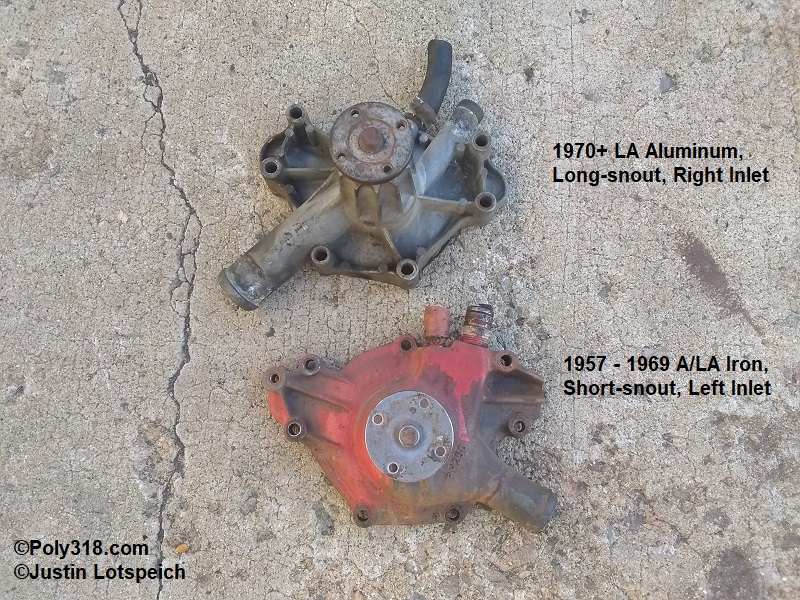

| Pulley, Water Pump, 1956 – 1969 | A-block and LA | Shallow pulley needed when using 1956 – 1969 cast-iron, short-shaft pump with left (driver) side intake (Figures 3a). |

| Pulley, Water Pump, 1970 – 1992 | LA | Deep pulley needed when using 1970 – 1992, long-shaft aluminum pump with right (passenger) side intake. (Figures 3a). |

| Pushrods, Stock, Mechanical Lifters | A-block 1956 – 1967 | Melling MPR55 or Sealed Power RP3030 (5/16” x 8.418”) WARNING: Due to wear and possible rebuild machine work on parts, pushrod length should always be checked. |

| Pushrods, Stock, Hydraulic Lifters | A-block 1956 – 1967 | Melling MPR153 (5/16” x 8.364”) WARNING: Due to wear and possible rebuild machine work on parts, pushrod length should always be checked. |

| Pushrods, Custom, High Performance | Custom for Performance or LA Lifters | I use Smith Brothers for custom chromoly 5/16″ x 0.083″ wall (they also offer thicker wall and titanium). |

| Rocker Arm Adjuster Screws | Factory Style: Sealed Power MR1933 Positive Locks: 3/8″-24 Threads | Note: The MR1933 are likely to go out of production, and stock is becoming limited through suppliers. |

| Rocker Arm Shaft Expansion Plugs | See Notes | A-block shafts used two different inside bores. Either use a 5/8″ plug (Pioneer EPC52) or a 11/16″ plug (Dorman 555-082 or Melling PC144) See the cylinder head tech article for information on cleaning the rocker shaft. |

| Sealant, Threaded Fasteners and Plugs | Permatex 80003 | I use it on oil and coolant pipe plug, expansion plugs, etc. |

| Sealant, Silicone, Permanent | Mopar RTV 4883971 | I use it whenever a gasket requires silicone sealant, such as the intake manifold, oil pan, etc. It is superior to Permatex RTV. |

| Sealant, Silicone, Temporary Tack | Permatex High Tack 80062 | I use it for temporarily holding gaskets in place during mock-up. I don’t use it for permanent installation since the fast cure makes it a weaker silicone. |

| Sealant, Silicone, Exhaust | Permatex Ultra Copper 81878 | When needed, I use it on exhaust components. |

| Sealant, Gasket Maker | Permatex 80019 | |

| Spark Plugs | 3/8″ Short-reach Only | I prefer Autolite 85. Champion 63 (formerly J12Y) is another option or cross-reference for another brand. Note: Some people claim that running any spark plug other than a Champion will mess with and harm the ignition system because they think the ignition system was designed specifically for Champion. This claim is mistaken, and any reputable spark plug brand will work with the Mopar points or electronic ignition system. WARNING: Do not install LA-type 3/4″ long-reach plugs, such as Autolite 65. They will contact the piston. |

| Starter Motor | See Notes | See the starter motor page for a full discussion of the different starter motor options. |

| Thermostat | A-block and LA | 180° Standard-flow: Stant 45358 180° 50% Higher Flow, My Preference: MotoRad 2006-180 (note that Tuff Stuff repackages this MotoRad thermostat and charges twice as much). 195° Standard-flow: Stant 45359 195° 50% Higher Flow: MotoRad 2006-195 (note that Tuff Stuff repackages this MotoRad thermostat and charges twice as much). Note: A high-flow thermostat is a good idea on all engines. It should be used if running a high-flow water pump. See the cooling system page for thermostat selection and diagnostics. WARNING: Running a 160° or no thermostat will not resolve overheating. If it were only that easy. |

| Timing Cover Dowels Iron Covers | A-block and LA Timing Cover or Cylinder Head Dowels | 0.390″ diameter x 1/2″ – 3/4″ long |

| Timing Set | A-block and LA | Cloyes C3002K (OEM-type single non-roller) Cloyes C3028X (double roller w/ cam advance adjustment) Cloyes 93503X9 (billet double roller w/ cam advance adjustment) |

| Timing Set Cover Iron, 1956 277/303 | A-block and LA with Modification. See Notes. | 1956 A-block 277 and 303 covers are iron, unique from all other A/LA, and are not reproduced (Figure 4a). The casting number is 1618684. |

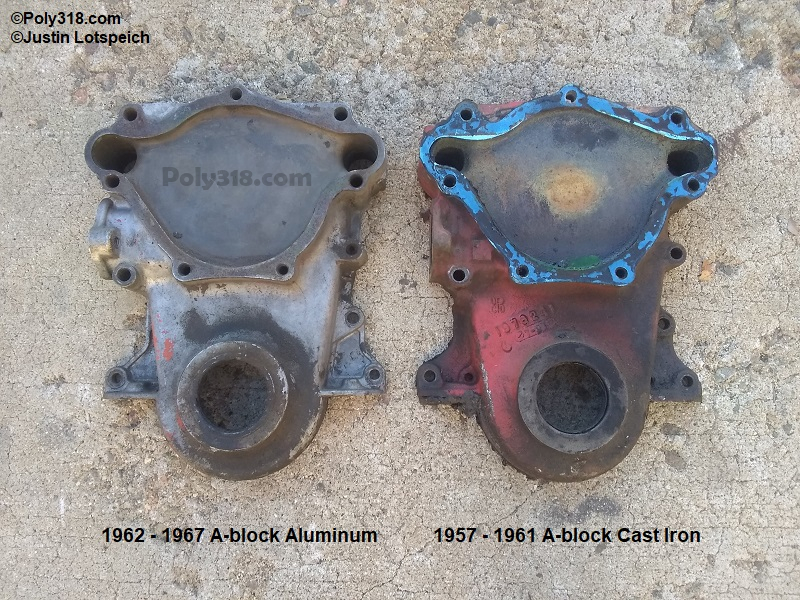

| Timing Set Cover Iron, 1957 – 1961 | A-block and LA with Modification. See Notes. | 1957 – 1961 A-block covers are iron and not reproduced (Figure 4b). These are excellent covers because the thick cast iron does not corrode anywhere nearly as bad as later aluminum covers. The cover can be used on all 1957 – 1967 A-blocks. 1962 – 1967 aluminum A-block covers interchange with the 1957 – 1961 A-blocks (Figure 4b). 1964 onward LA273/318/340 aluminum covers can be made to work: Allstar ALL90028 or Dorman 635-400. Note: The LA cover has the timing marker cast in on the left, whereas the A-block damper timing mark is clocked on the right. There is also a missing bolt hole on the 1970 onward cover that requires plugging in the block. See the timing cover and water pump installation tech article for details. |

| Timing Set Cover Aluminum, 1962 – 1967 | A-block and LA with Modification. See Notes. | 1962 – 1967 aluminum A-block covers interchange with all the 1957 – 1967 A-blocks. They are unique from LA covers in that they have an additional bolt hole and do not have a timing marker. 1964 onward LA273/318/340 aluminum covers can be made to work: Allstar ALL90028 or Dorman 635-400. Note: The LA cover has the timing marker cast in on the left, whereas the A-block damper timing mark is clocked on the right. There is also a missing bolt hole on the 1970 onward cover that requires plugging in the block (Figure 4c). See the timing cover and water pump installation tech article for details. |

| Valves, Exhaust, 1956, 277/303 | See notes | 1956 277/303 used a slightly different valve than later A-blocks. Factory: 1.562″ diameter, 4.484″ long, 0.372″ stem diameter Note: Exhaust valves can be taken to 1.625″” safely. Custom race valves can be ordered through REV Racing Engine Valves. |

| Valves, Exhaust, 1957 – 1958, All | A-block or Custom See note about 313 | Factory: 1.560″ diameter, 4.580″ long, 0.372″ stem diameter Note: Export 313 heads may have slightly larger valve head diameter. Note: Exhaust valves can be taken to 1.625″” safely. Custom race valves can be ordered through REV Racing Engine Valves. |

| Valves, Exhaust, 1959 – 1961, All | A-block or Custom See note about 313 | Factory: 1.563″ diameter, 4.450″ long, 0.372″ stem diameter Note: Export 313 heads may have slightly larger valve head diameter. Note: Exhaust valves can be taken to 1.625″” safely. Custom race valves can be ordered through REV Racing Engine Valves. |

| Valves, Exhaust, 1962 – 1967, All | A-block or Custom See note about 313 | Factory: 1.563″ diameter, 4.530″ long, 0.372″ stem diameter Note: Export 313 heads may have slightly larger valve head diameter. Note: Exhaust valves can be taken to 1.625″” safely. Custom race valves can be ordered through REV Racing Engine Valves. |

| Valves, Intake, 1956, 277/303 | A-block or Custom See note about 313 | Factory: 1.844″ diameter, 4.547″ long, 0.373″ stem diameter Note: Export 313 heads may have slightly larger valve head diameter Note: Intake valves can be taken to 2.02″ safely. Custom race valves can be ordered through REV Racing Engine Valves. |

| Valves, Intake, 1957 – 1958, All | A-block or Custom See note about 313 | Factory: 1.840″ diameter, 4.60″ long, 0.373″ stem diameter Note: Export 313 heads may have slightly larger valve head diameter Note: Intake valves can be taken to 2.02″ safely. Custom race valves can be ordered through REV Racing Engine Valves. |

| Valves, Intake, 1959 – 1961, All | A-block or Custom See note about 313 | Factory: 1.844″ diameter, 4.510″ long, 0.373″ stem diameter Note: Export 313 heads may have slightly larger valve head diameter Note: Intake valves can be taken to 2.02″ safely. Custom race valves can be ordered through REV Racing Engine Valves. |

| Valves, Intake, 1962 – 1967, All | A-block or Custom See note about 313 | Factory: 1.844″ diameter, 4.590″ long, 0.373″ stem diameter Note: Export 313 heads may have slightly larger valve head diameter Note: Intake valves can be taken to 2.02″ safely. Custom race valves can be ordered through REV Racing Engine Valves. |

| Valve Cover, Bolt Washers | See Notes | Early A-blocks used a thick, cupped washer. I discovered that skateboard truck washers are almost identical. |

| Valve Springs | A-block and LA Match Camshaft Specs See Notes | A-block and LA share the same spring diameter and install height (1.625 – 1.6875″). Replacements for a factory A-block camshaft grind are Melling VS150. Springs must meet the camshaft specifications, fit the valve seal, and meet the correct install height. WARNING: Rocker arm travel across the valve tip should be checked for proper geometry. |

| Valve Spring Keepers | See Notes | 7° or 10° are available and should be matched to the valve stem diameter, groove type, and retainer angle. |

| Valve Spring Retainers | See Notes | Should be matched to the valve spring, valve stem diameter, and keeper angle. |

| Valve Stem Seals | See Notes | The seal depends on the valve stem diameter (3/8″ stock but available in 11/32″ and 5/16″) and how the machinist turns down the guide. Consult the machinist. 3/8″ Stem Positive Seal: FelPro SS72730 is common 3/8″ Stem Umbrella: FelPro SS70014 is common |

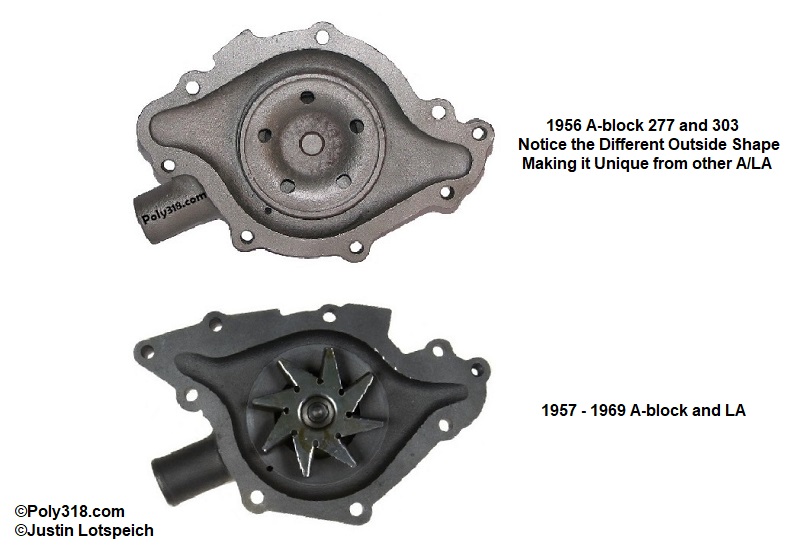

| Water Pump, 1956, Iron, Left Intake | A-block 277/303 Only | Unique Pump, short shaft, requires a shallow pulley (Figure 5a). Casting/part numbers include 1632079 and 1643173. Save used units to rebuild since rebuilt and NOS units are getting difficult and expensive to locate. |

| Water Pump 1957 – 1969, Iron, Left Intake | A-block and LA | Short shaft, requires shallow pulley (Figures 5b). OEM Type: WP58180, TFW43030 High-flow: FlowKooler 1701 See the cooling system page for pump selection and installation. WARNING: Depending on the cooling system, a high-flow pump can actually move the coolant too quickly through the system to where heat from the engine does not have sufficient time to disperse into the coolant and the heat in the coolant does not have time to disperse into the radiator metal. In these cases, a standard-flow pump will actually cool the engine better. |

| Water Pump 1970 onward Aluminum, Right Intake | LA | Long shaft, requires deep pulley (Figures 5b). OEM Type: WP58181, TFW43026 High-flow model: Tuff Stuff 1465NA See the cooling system page for pump selection and installation. WARNING: Depending on the cooling system, a high-flow pump can actually move the coolant too quickly through the system to where heat from the engine does not have sufficient time to disperse into the coolant and the heat in the coolant does not have time to disperse into the radiator metal. In these cases, a standard-flow pump will actually cool the engine better. |

.