Poly 318 Starter Motors

(applicable to LA, B, RB, Slant 6 engines)

Starter Categories

Since my starter discussion applies to almost all 1956 – 2003 Mopar engines, I start by saying that the information in this article applies to 1956 – 1961 A, B, and RB blocks and 1962 – 2003 A, LA, B, RB, Slant 6, and Magnum engines. The starters fall into five categories to choose from depending on the engine year, clearance restrictions, and amount of motor torque required: 1956 – 1961 A/B/RB factory, 1962 – 1987 factory, 1988 – 2003 Magnum factory, A/LA/B/RB aftermarket high-torque, and Magnum high-torque.

1956 – 1961 A , B, and RB Factory Starter

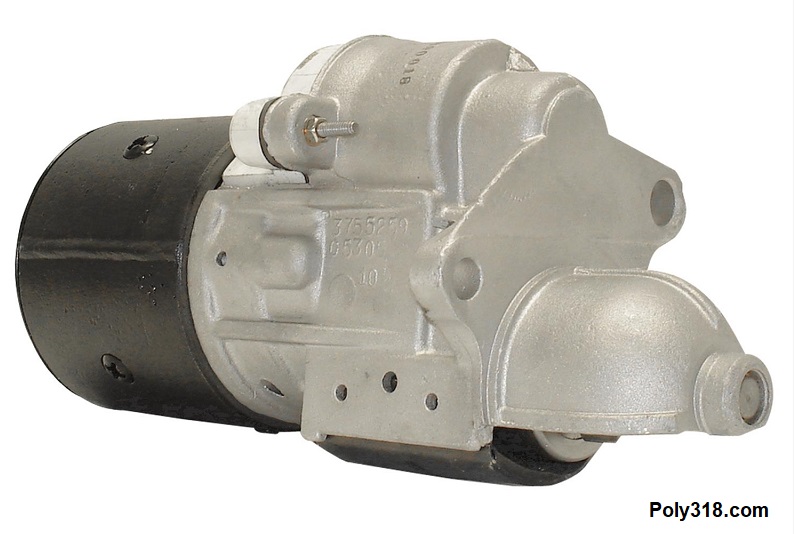

Unfortunately, early automatic and standard transmission A-block owners are very limited with starters sold off the shelf. Most 1956 – 1961 A, B, and RB automatic transmission factory starters interchange with the 1956 – 1961 A-block. These are designed for the 172-tooth torque converter ring gear and usually have 10 teeth (OEM) or 9 teeth (reduced high-torque). Part numbers for OEM torque include but are not limited to Autolite 1779955, 1842562, 1889260, and 1889295 (Figure 1a).

A-blocks with standard transmissions from 1956 – 1964 used the same starter, Autolite 1889200. The starter is designed for a 146-tooth flywheel.

Both the automatic and standard starter are long and bulky, do not incorporate the solenoid, and cannot be substituted for a 1962+ automatic starter motor. Both the automatic and standard starters are getting harder to source through parts stores–unless you find a very dusty one hidden in a corner–and are getting harder and expensive to source through specialty suppliers due to the lack of cores. Keep cores to have them rebuilt or at the very least to see if a rebuilder wants them rather than scrapping them.

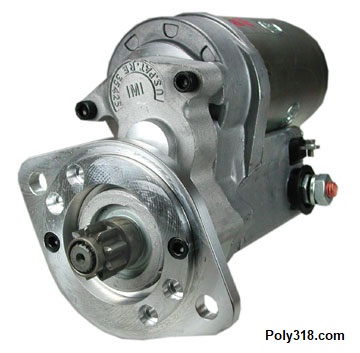

The one high-torque automatic-transmission starter I know of for the 1956 – 1961 A-block is made by IMI High Torque, Model 138 (Figure 1b). Do an internet search for the starter since IMI has multiple distributors and the prices change. Be forewarned that it’s an expensive starter. Verify the ring gear teeth prior to purchasing.

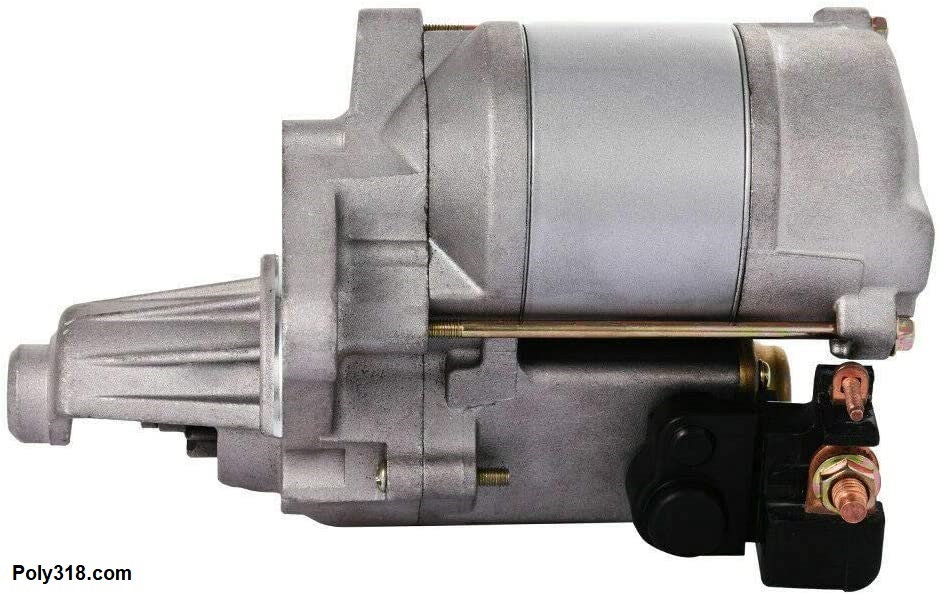

1962 – 1987 A, LA, B, RB, Slant 6 Factory Starter

The 1962 A-block redesign included the starter motor for automatic transmission vehicles that eventually became the chosen starter for all Mopar V8 and Slant 6 engines through 1987 (Figure 2). These starters are designed for a 130-tooth ring gear. 1962 – 1987 starters will work on the 1962 – 1967 A-block including but not limited to part numbers Autolite 2095150 and ACDelco 33611042, 3361043, 3361044. These starters are readily available through parts houses new and remanufactured. They are a long and bulky design and usually create clearance issue when running headers. They incorporate a solenoid and crank out 1.1 kW 1.47 HP with a 10-tooth gear.

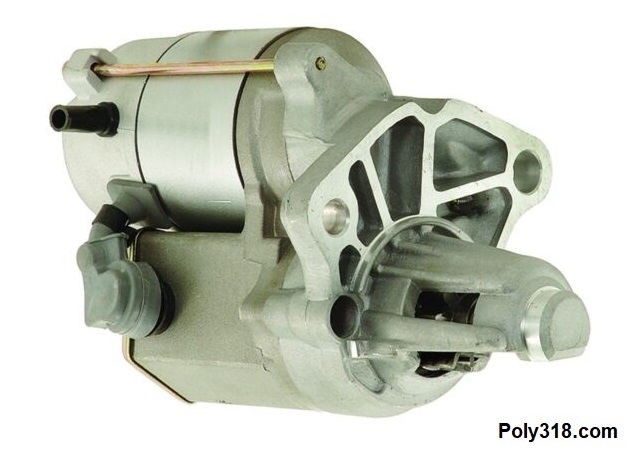

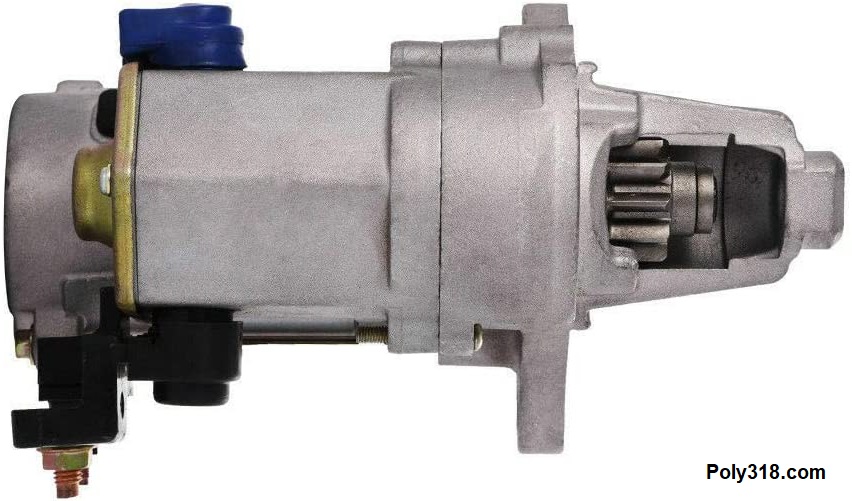

1988 – 2003 Magnum Factory Starter (commonly called the “mini Denso”)

Along with the introduction of the Magnum small block in 1988 came a new starter motor designed by Denso that can be used on 1962 – 1987 V8 engines including the A-block (Figures 3 – 6). The design was used on 5.2 and 5.9 V8s from 1988 – 2003 and the 3.9 V6 from 1992 – 2002 in vehicles such as the Dakota, Ram, Durango, etc. The design went through four subtle changes that did not impact the overall dimensions or power: 1988 – 1990 (ACDelco 3371094), 1991-1995 (3371096), 1996 – 1998 (3371100), and 1999 – 2003 (3371155). The starter is a compact design and is commonly called a “mini” starter. The “mini” nickname is somewhat of a misnomer because there is no such thing as a “mini” Magnum starter since they are all the same compact size unlike a factory GM starter and an aftermarket “mini” GM starter. They incorporate the solenoid and crank out 1.4 kW, 1.87 HP with a 10-tooth gear. They can reliably handle compression ratios up to 10:1 and have been reported to handle up to 11:1 if insulated from exhaust heat and with properly sized battery and wire. Note that the black electrical connector extension pictured in Figure 5 may be removed for clearance.

Standard Transmission Note: If using the Magnum-style starter with a standard transmission A-block, the flywheel will be too small in diameter to engage the starter gear. The easiest solution is to obtain a later neutral-balanced flywheel, such as from a 1987 Dodge D250 with a 318. This flywheel is larger diameter and will contact the Magnum starter gear.

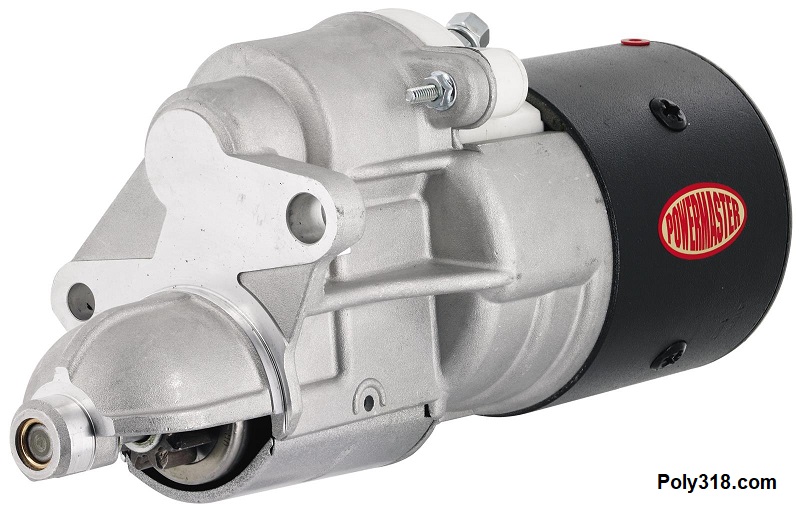

1962 – 1987 High Torque Starter

Aftermarket manufacturers produce a high-torque starter based off the 1962 – 1987 unit, such as Powermaster 3257 (Figure 7). The units incorporate the solenoid and crank out 1.4 kW, 1.8 HP with a 10-tooth gear. Powermaster recommends compression ratios up to 10:1.

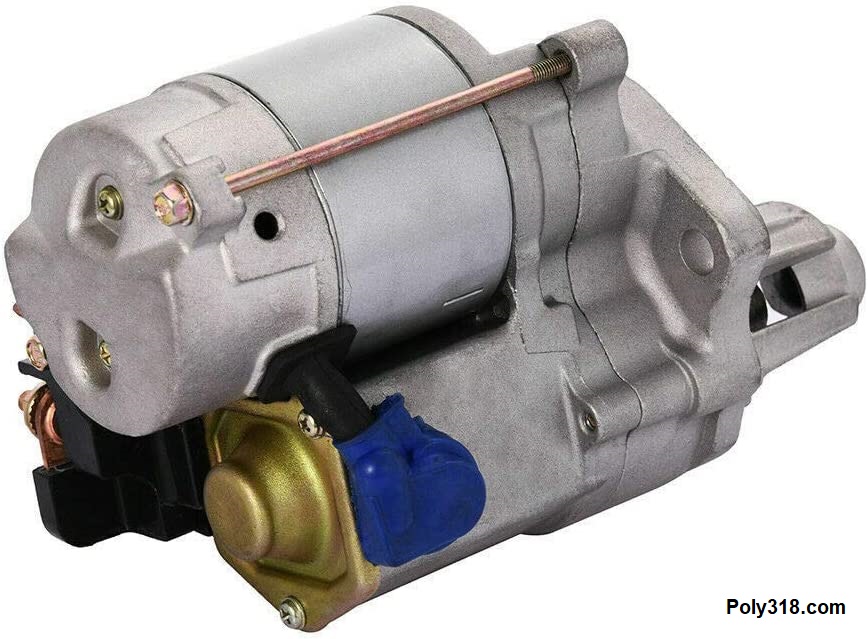

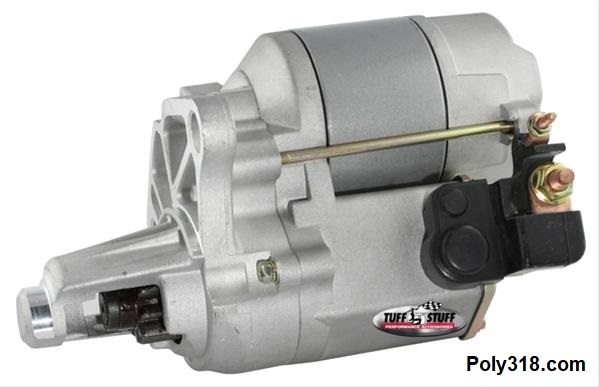

1988 – 2003 Magnum High Torque Starter

Aftermarket manufacturer produce a high-torque starter based off the 1988 – 2003 Magnum Denso starter, such as Tuff Stuff Performance 6084B (Figure 8). The units incorporate the solenoid and share the same compact housing as the factory Magnum starter. They crank out 1.61 kW, 2.5 HP with a 9-tooth gear and are rated up to 15:1 compression.

Standard Transmission Note: If using the Magnum-style starter with a standard transmission A-block, the flywheel will be too small in diameter to engage the starter gear. The easiest solution is to obtain a later neutral-balanced flywheel, such as from a 1987 Dodge D250 with a 318. This flywheel is larger diameter and will contact the Magnum starter gear.

Grinding, Clunking, and Other Noises During Starting

Unlike other manufacturers, Mopar starters do not use shims to adjust the clearance between the starter gear and the converter/flywheel ring gear. Many factory A, LA, B, RB starters used a sheet metal shield between the starter and bellhousing to keep debris out of the bellhousing cavity, but this is not a shim and has no impact on the clearance between the gears. (As an aside, the LA/B/RB shield leaves a large hole when using the Magnum starter, so one can either make a shield or order one from 440 Source (part 122-1001). If the starter is making a grinding or clunking noise, there is a good chance it is either malfunctioning or has an issue with the case tolerances. If the bolt holes and/or housing pilot that registers into the transmission case are hogged out from wear/rebuilding or otherwise machined incorrectly, the starter gear may be too close to the the converter/flywheel ring gear creating the grinding. If the starter gear isn’t retracting properly, it may be catching on the ring gear as the engine spins up. These issues are more common on remanufactured units with worn-out housings but can happen on new starters due to quality control issues.