Poly 318, Polyspherical, LA, and Magnum Parts Interchange

(Covers 277, 301, 303, 313, 318, and 326 A-blocks)

Introduction

I have compiled this list of poly 318 parts interchange with polyspherical, LA 318 273, 340, 360, and Magnum engines with notes to assist in piecing together engines. The database covers 1956 – 1967 A-block 277, 301, 303, 313, 318, and 326. For part numbers and recommendations, see the complete A-block parts list. Note that many of the interchangeable parts below can be found new through retailers such as Rock Auto, Napa, Summit Racing, and Jegs.

| Component | A-block Year Range | A-block Interchange | LA and Magnum Interchange | Notes |

|---|---|---|---|---|

| Blocks | 1956 – 1957 | 277 | No Interchange | Unique to 277 |

| 1957 – 1961 | 301/313/318/326 | No Interchange | 301 and 313 are underbored 318 blocks and must be bored to 3.91 minimum to use standard 318 pistons. 326 is overbored 318 block and can be used with overbore replacement 318 pistons. |

|

| 1962 – 1967 | 313/318 | No Interchange | 313 are underbored 318 blocks and must be bored to 3.91 minimum to use standard 318 pistons. | |

| Camshaft | 1956 – 1967 | All A | No Interchange | A-block camshafts interchange. Note that the wedge LA camshafts are completely different from the canted-valve A-block. The A-block has a lobe configuration starting at cylinder one running back of exhaust/intake/exhaust/intake/etc.; the LA has a configuration of exhaust/intake/intake/exhaust/etc. Cast blanks are no longer produced and are getting difficult to source. The cheapest option if the used camshaft is a good core is to have it reground. See the page on camshafts for recommended cam grinders and specifications. Another option is to have a new camshaft machined from billet, although this is a more expensive option for flat-tappet lifters and argues for doing the work to convert the engine to roller lifters with a billet roller camshaft. Note that a reground camshaft may require longer pushrods, which should be checked during mock-up. Mechanical-lifter camshafts require adjustable rocker arms. Factory hydraulic-lifter camshafts used non-adjustable rocker arms that are wise to change to adjustable even if using a hydraulic camshaft in order to precisely adjust preload. |

| Camshaft Bearings | 1956 – 1978 | All A | 1964 – 1978 LA | 1979 onward cam bearings changed and do not interchange. |

| Connecting Rods | 1956 – 1957 | 277/301/303 | No Interchange | 277, 301, 303 use the 277 rod that differs from other A-blocks. |

| Connecting Rods | 1957 – 1967 | 313/318/326 | 1964-1967 LA273/318 rods bushed for full-floating pins are identical to A-block and directly interchange. LA340 rods bushed for full-floating pins will work in an A-block but do not directly interchange. Note that some heavy duty LA318 from 1968 – 1973 received the same LA340 rods. These LA340 rods are heavier than A-block and must not be mixed in with them. 1971 onward LA318 and LA360 rods with pressed-pins will work but do not directly interchange. These pressed-pin rods are heavier than A-block and must not be mixed in with them. | |

| Connecting Rod Bearings | 1956 – 1967 | All A | All LA | WARNING: Aftermarket forged crankshafts usually require narrow bearings such as Clevite CB481HN due to a larger radius on the journals. Consult the crank manufacturer and verify during mock-up. |

| Crankshaft | 1956 – 1957 | 277/301 | No Interchange | 277 and 301 cranks share 3.125 stroke. |

| 1957 – 1961 | 303/313/318/326 | No Interchange | Cranks have 1/2 longer 8-bolt rear flange for PowerFlite, TorqueFlite A466, and standard transmissions. Will not interchange with 1962 – 1967. Requires a transmission adapter system to use 1962 onward transmissions.See the crankshaft page for more details and photos. | |

| 1962 – 1967 | 313/318 | 273/318/340 Internal Balance | Using different crankshaft requires balancing rotating assembly. | |

| Cylinder Heads | 1956 – 1961 | All A See note about 313 | No Direct Interchange | 1956 – 1960 heads do not have accessory bosses drilled/tapped on one end. Once installed on the engine, there will be no threaded bosses on the right (passenger) front end of the head; the left (driver) front end has a single threaded boss. These heads have an extra coolant port that is missing from 1962 onward A blocks. The heads can be made to interchange on 1962 onward A and LA blocks by plugging the holes. The export 313 cylinder heads on the “Full-premium” engine (usually found in heavy trucks) has oddball 18mm spark plugs and slightly larger valves than the other A-block cylinder heads. They are undesirable due to the 18mm spark plug. |

| 1962 – 1967 | 1956 – 1967 All See note about 313 | No Direct Interchange | These heads can be used on 1956 – 1961 A blocks without modification. The heads have four threaded accessories bosses on one end and either one or two on the other. Once installed on the engine, there will be four threaded bosses on the right (passenger) front end of the head; the left (driver) front end will have one or two threaded bosses. The export 313 cylinder heads on the “Full-premium” engine (usually found in heavy trucks) has oddball 18mm spark plugs and slightly larger valves than the other A-block cylinder heads. They are undesirable due to the 18mm spark plug. They have a cooling port that is open to the lifter valley when fit on an LA block. The heads can be made to interchange on LA blocks by plugging the holes. |

|

| 1962 – 1967 “M” | 1959 – 1967 Marine | No Direct Interchange | A head with a large M cast under the valve cover are for marine applications and have special tapped cooling ports (see Figures 1a – 1c). They use the same casting numbers as automotive heads. They can be used on 1956 – 1967 A blocks by plugging the special coolant ports.See the marine page for more details. | |

| Distributor | 1962 – 1967 | All A | All LA | |

| Distributor Drive Gear | 1956 – 1967 | All A | All LA | |

| Exhaust Manifolds | 1956 – 1967 | All A | No Interchange | Exhaust manifolds can be used on either right or left head. A-block cars often came with one center-dump and one rear outlet. A-block trucks often came with two center-dump. Generator engine right manifolds had a generator bracket incorporated.See the exhaust-manifold page for photos.See the exhaust-manifold installation tech article. |

| Flywheel | 1956 – 1961 | All A | No Interchange | 1956 – 1961 with automatics did not use a flexplate and had the torque converter bolt directly to the crank. |

| Flywheel/Flexplate | 1962 – 1967 | All A | 273/318/340 Internal Balance | LA360 and cast-crank LA340 flexplates/flywheels can either be neutral balanced or weighted to balance the rotating assembly. Using them on the A-block requires verifying they are neutral balanced. Check flywheel teeth for matching with starter motor. |

| Fuel Pump | 1956 – 1967 | All A | All LA | |

| Fuel Pump Eccentric | 1956 – 1967 | All A | All LA | |

| Harmonic Damper | 1956 – 1967 | All A | 273/318/forged crank 340 – neutral balanced | The A-block never used a harmonic balancer since they are internally balanced. When using an internally balanced LA harmonic damper with an A-block timing cover, see the notes under “Timing Cover” below and the page on harmonic dampers for more details on interchanging dampers and timing covers since the timing marks may not align. LA360 and cast-crank LA340 are externally balanced via the balancer and will throw the A-block rotating assembly out of balance if used.See the timing cover and damper page for interchange details. 1970 – 1992 and most aftermarket LA dampers have a slightly different pulley bolt pattern, so using a 1970 – 1992 damper with an A-block pulley requires elongating pulley holes, which will not have a negative impact on anything. |

| Intake Manifold | 1956 – 1967 | All A | No Interchange | Unique to A-block.See the intake manifold page for options.See the intake-manifold installation tech article. |

| Lifters (Mechanical) | 1956 – 1967 | All A | No Direct Interchange | Both A-block and LA lifters share the same 0.904 lifter diameter, but the A lifter is shorter. The longer LA lifters can be used but require shorter custom-length pushrods. |

| Lifters (Hydraulic) | 1956 – 1967 | All A | No Direct Interchange | Both A-block and LA lifters share the same 0.904 lifter diameter, but the A lifter is shorter. The longer LA lifters can be used but require shorter custom-length pushrods. |

| Main Bearings | 1956 – 1967 | All A | 1964 – 1973 273/318/340 | 1956 – 1973 A-blocks and LA273/318/340 main bearings interchange and use a thrust bearing with a short vertical thrust side, such as Clevite MS540P. The overall diameter of this thrust bearing when installed is 3.374″. These bearings feature an oil groove on one half of the bearing and solid on the other. Depending on the factory machining, some A-blocks have the thrust bearing block webbing and main cap sides machined with a short rabbit to match the short thrust bearing side, although some blocks had a taller rabbit machined in. 1974 onward LA318/340 blocks have the thrust bearing webbing and main cap sides machined with a taller rabbit and use a thrust bearing with a taller vertical thrust side for additional support, such as Clevite MS1344P. The overall diameter of this thrust bearing when installed is 3.53″. The bearings feature a full oil groove on both halves. Before purchasing 1974 onward LA318/340 main bearings with full oil grooves to use in a 1956 – 1973 A or LA block, one must verify that the block webbing and main cap are machined with tall enough rabbits for the taller 1974 onward thrust bearing to fit. If the rabbit is not tall enough and the 1974 onward bearing is used, the bearing will not fully seat into the block and will bind on the crankshaft main journal. If the use of the full oil groove 1974 onward main bearings is desired, you can either have the block/main cap rabbit machined taller, you can sand down the thrust bearing sides, or you can obtain a 1956 – 1973 thrust bearing and use the 1974 onward bearings on the other main journals. Note that aftermarket forged crankshafts usually require narrow bearings such as Clevite MS540H due to a larger radius on the journals. Consult the crank manufacturer and verify during mock-up. |

| Oil Filter, Housing (Cartridge) | 1956 – approx. 1962 | All A | See Notes | Generation 1 Hemi and Hemi-block poly interchange. The block can be fitted with an LA or aftermarket spin-on adapter. WARNING:Read the oil bypass valve and filter page because many early engines have the oil constantly bypassing the filter. |

| Oil Filter (Spin-on) | 1962 – 1967 | All A | All LA | |

| Oil Pan | 1956 – 1967 | All A | 273/318/340 | 1956 – 1958 pans were 5-quart (Figure 2a). 1959 – 1967 car pans were 4-quart (Figure 2b). 1959 – 1967 pans were 4-quart front sump to clear the suspension (Figure 2c). 1959 – 1967 A marine were 8-quart (Figure 2d). The oil pump pickup must match the pan configuration. |

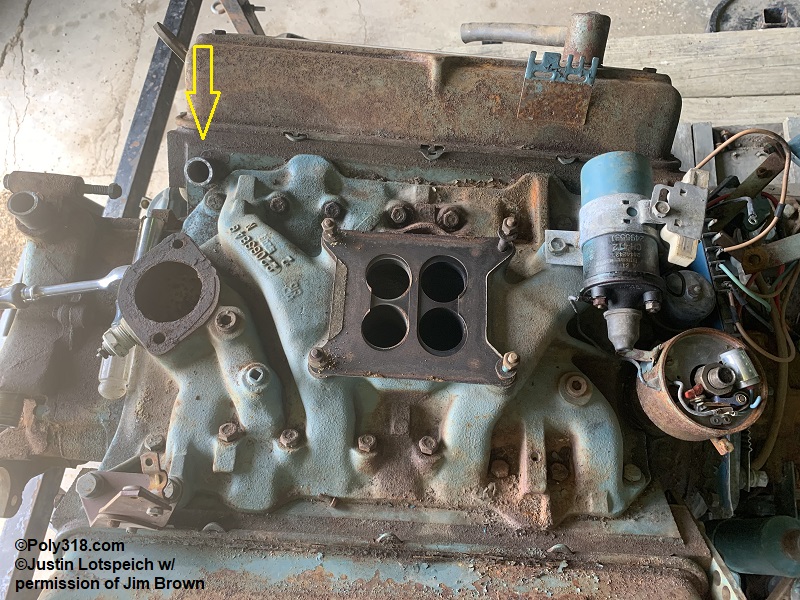

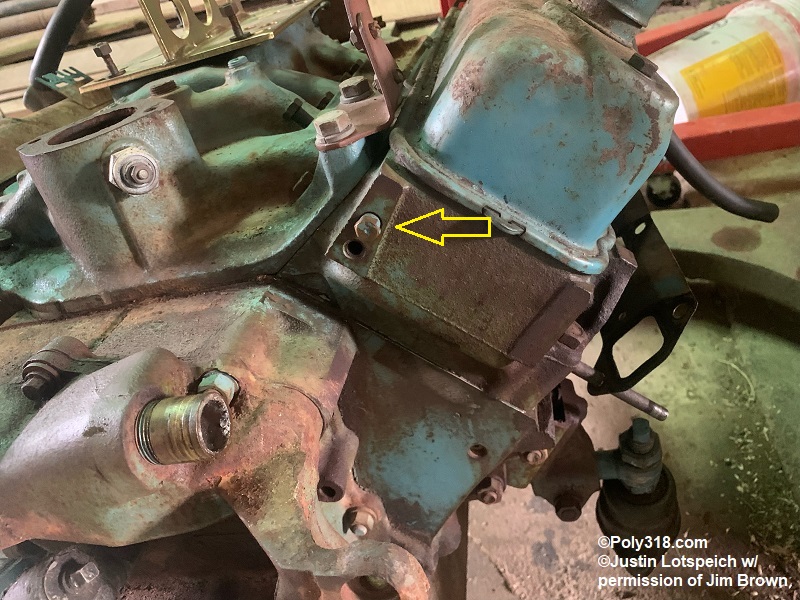

| Oil Pump | 1956 – 1961 | All A | No Interchange | Early pump seen in Figure 3a. |

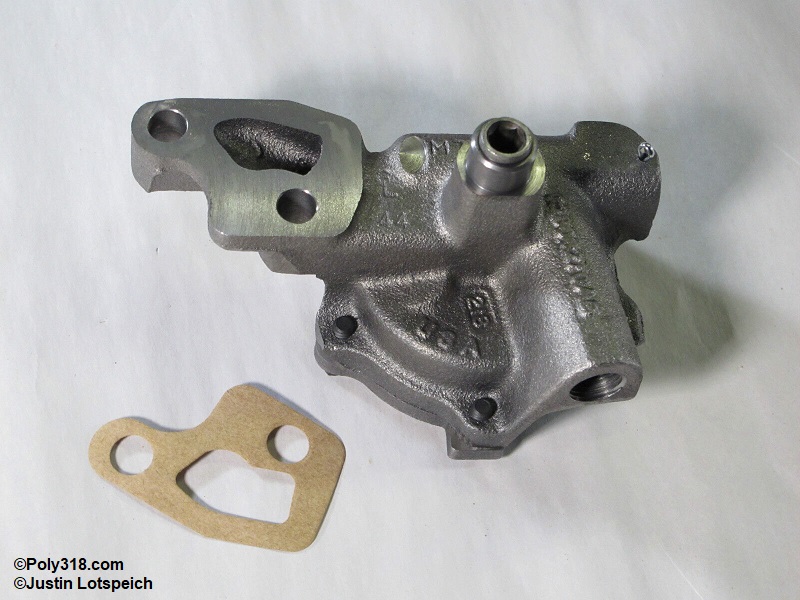

| 1962 – 1967 | All A | All LA | (Figure 3b) | |

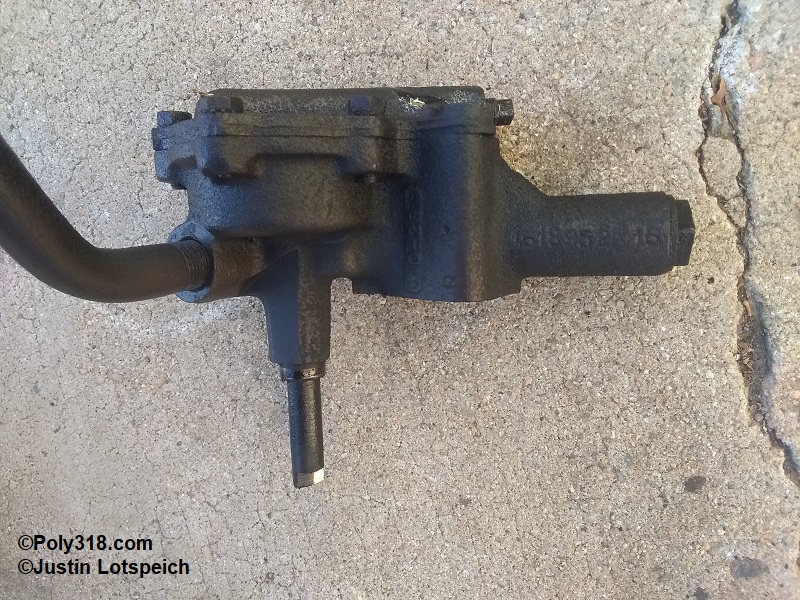

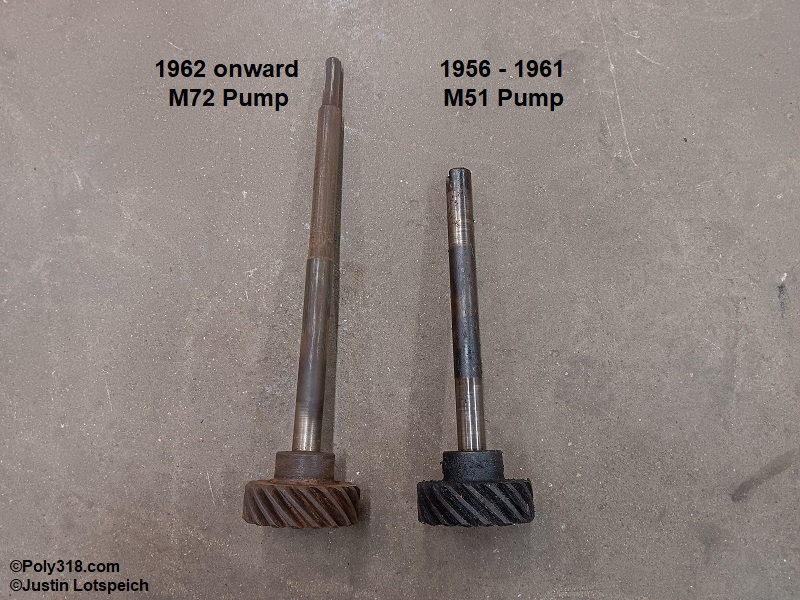

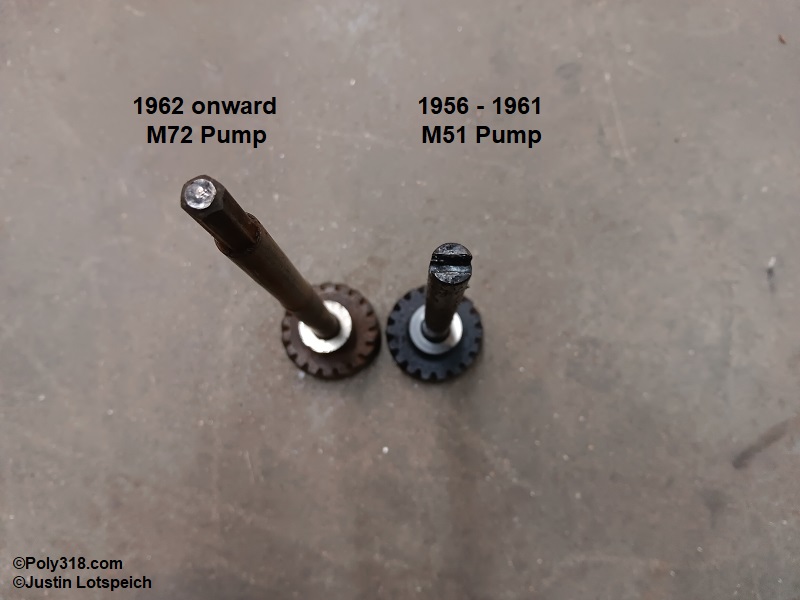

| Oil Pump Intermediate Drive Shaft | 1956 – 1961 | All A | No Interchange | The M51 pump uses a tang rotor that accepts a slotted shaft (Figures 3c – 3d). |

| 1962 – 1967 | All A | All LA | The M72 pump uses a hex rotor that accepts a hex shaft (Figures 3c – 3d). | |

| Pistons | 1956 – 1967 | All w/ Matched Bore | No Direct Interchange | LA 318 flat-top pistons without valve reliefs can be made to work by fly-cutting valve reliefs for the A-block valves (Figure 4). 340 flat-top pistons can be made to work the same but require sonic-testing the block for overbore that much. |

| Piston Rings | 1956 – 1967 | See Notes | See Notes | Piston rings are not unique to the A-block. Match rings to block bore and piston groove sizes. |

| Pulley (Crank) | 1956 – 1967 | All A | All LA | Match belt quantity to accessories. 1970 – 1992 LA273/318/340/360 pulleys have a slightly different pulley bolt pattern, so using a 1970 – 1992 pulley on a pre-1970 damper requires elongating pulley holes, which will not have a negative impact on anything. |

| Pulley (Water Pump) | 1956 – 1967 | All A | All LA | 1956 – 1969 water pumps have a short shaft and shallow pulley, and 1970 onward water pumps have a long shaft and deep pulley (Figure 5). Match belt quantity to accessories. |

| Pushrods (Mechanical Lifters) | 1956 – 1967 | All A w/ Mechanical | No Interchange | |

| Pushrods (Hydraulic Lifters) | 1956 – 1967 | All A w/ Hydraulic | No Interchange | |

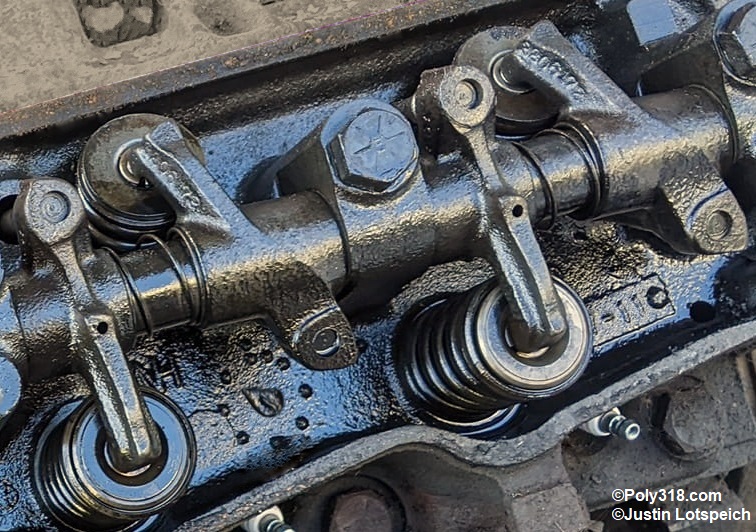

| Rocker Arms (Adjustable) | 1956 – 1967 | All A | No Interchange | Will interchange onto non-adjustable A-block rocker shaft. Cast LA273/340 rocker arms do not interchange with A-block. |

| Rocker Arms (Non-adjustable) | 1956 – 1967 | All A | No Interchange | Figure 6a. Will interchange with adjustable A-block rocker shaft. Cast LA273/340 rocker arms do not interchange with A-block. |

| Rocker Arm Shafts | 1956 – 1967 | All A | No Interchange | Unique to A-block. LA, B, and RB shafts do not interchange. |

| Starter Motor (Automatic) | 1956 – 1961 | All A Automatic | LA standard when matched with converter teeth count | See page on starter motors for more details. |

| Starter Motor (Standard) | 1962 – 1966 Standard | All A Standard | LA standard when matched with flywheel teeth count | See page on starter motors for more details. |

| Starter Motor (Automatic) | 1962 – 1967 Auto | All A Automatic | LA and Magnum auto when matched with converter teeth count | See page on starter motors for more details. |

| Timing Set | 1956 – 1967 | All A | All LA | |

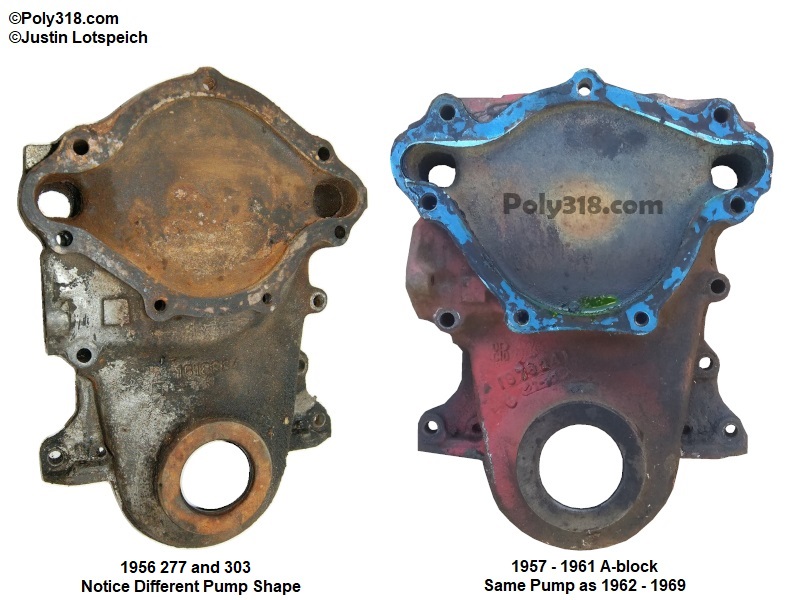

| Timing Cover (Iron) | 1956 | 277 and 303 | No Interchange | Unique to 1956 only (Figure 7a) See timing cover and water pump installation tech article. |

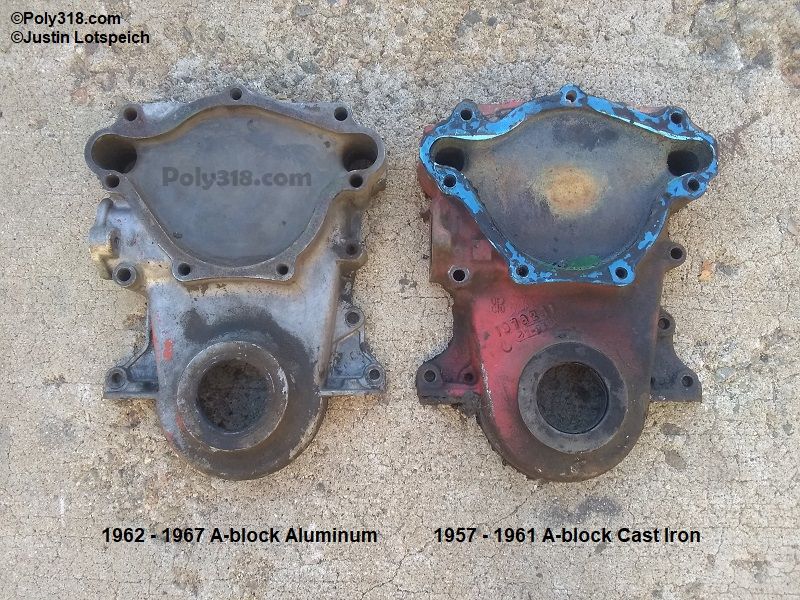

| Timing Cover (Iron) | 1957 – 1961 | 1957 – 1967 A | 273/318/340 | See timing cover and water pump installation tech article. The 1957 – 1967 A-block timing cover is cast iron with no timing marker (Figure 7b). LA273/318/340 covers will fit but lack one bolt hole on the left side (Figure 7c). In the A-block, this boss goes through into a water jacket. To use the LA timing cover on an A-block, plug the block hole using a set screw or cutoff bolt and Permatex 80003 sealant prior to installing the timing-cover gasket. If using an A-block damper with the TDC clocked on the right (passenger) with a 1970 onward LA timing cover with the molded timing marker on the left (driver), re-mark the damper TDC line with a file or timing tape with cylinder 1 at true TDC. If using a 1970 onward LA damper with a 1970 onward LA timing cover, the markers align. |

| Timing Cover (Aluminum) | 1962 – 1967 | 1957 – 1967 A | 273/318/340 | See timing cover and water pump installation tech article. The 1962 – 1967 A-block aluminum timing cover does not have a timing marker. LA273/318/340 covers will fit but lack one bolt hole on the left side (Figure 7c). In the A-block, this boss goes through into a water jacket. To use the LA timing cover on an A-block, plug the block hole using a set screw or cutoff bolt and Permatex 80003 sealant prior to installing the timing-cover gasket. If using an A-block damper with the TDC clocked on the right (passenger) with a 1970 onward LA timing cover with the molded timing market on the left (driver), re-mark the damper TDC line with a file or timing tape with cylinder 1 at true TDC. If using a 1970 onward LA damper with a 1970 onward LA timing cover, the markers align. |

| Thermostat | 1956 – 1967 | All A | All LA | |

| Thermostat Housing | 1956 – 1967 | All A | All LA Early Hemi/Hemi-block poly, B, RB | The factory A-block housing was the same casting as the early hemi/hemi-block poly and was also used on early LA. The neck is angled forward. No one reproduces the angled neck housing, but a straight-neck housing used on LA, B, and RB engines will work on an A-block since the thermostats, bolt spacing, and hose diameter are identical. To use a straight-neck housing on an A-block, use a 1-1/2″ hose with a 90° bend in it. Some Chevrolet housings will physically bolt to an A-block intake manifold and provide the angled neck, but Chevy used a smaller-diameter thermostat with the indexing well cut into the manifold compared to the larger Mopar thermostat with the well cut into the housing. To use a Chevy housing requires either machining a well into the A-block manifold pad or using a 1/8″ bead of RTV silicone to index the thermostat and seal the gap created by the thermostat sandwiched between the two flat pads. |

| Valves, Intake/Exhaust | 1956 – 1967 | See parts list | No Interchange | See the parts list since there are four variations of valves from 1956 -1967. |

| Valve Covers | 1956 – 1967 | All A | No Interchange | 1956 – 1958 and some 1959 have three bolt holes but will interchange with all year A-blocks (Figure 8). Most heads have the center bolt hole boss drilled and tapped through end of production in 1967. Those missing the center boss can be drilled and tapped. |

| Valve Springs | 1956 – 1967 | See Notes | See Notes | Springs are not unique to the A-block and can be purchased in different diameters, height, and rate. Follow camshaft requirement. Verify proper rocker-arm tip travel across valve tip. |

| Valve Spring Retainers | 1956 – 1967 | All A | See Notes | Retainers are not unique to the A-block and can be purchased in different diameters and keeper angles. Match retainer to valve stem and spring diameters and keeper angle. |

| Valve Spring Keepers | 1956 – 1967 | See Notes | See Notes | Keepers are not unique to the A-block and can be purchased in different diameters, angles, and grooves. Match keepers to valve diameter, grooves, and retainer angle. |

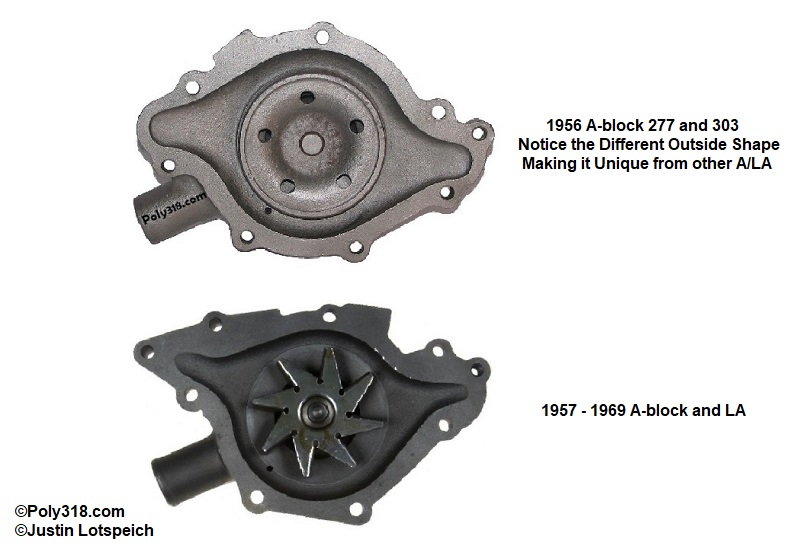

| Water Pump, Left Intake (Iron) | 1956 | 277 and 303 | No Interchange | Unique to 1956 with a different shape than all other A-block and LA (Figure 9a). Short shaft, requires shallow pulley. |

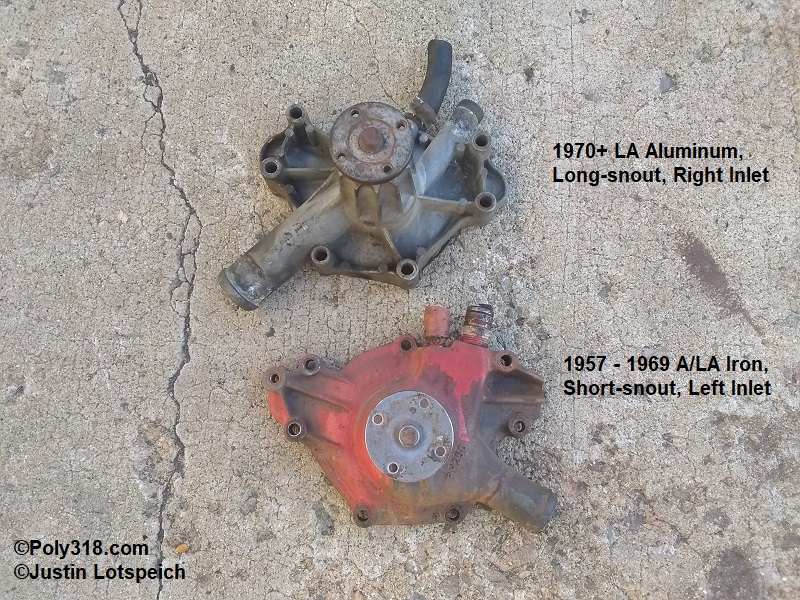

| Water Pump, Left Intake (Iron) | 1957 – 1967 | 1957 – 1967 A | 1964 – 1969 LA | 1957 – 1969 iron pump has left (driver) side intake (Figure 9b). Short shaft, requires shallow pulley (Figure 5).See the water pump installation tech article. |

| Water Pump, Right Intake (Aluminum) | 1957 – 1967 | 1957 – 1967 A | 1970 onward LA | 1970 onward aluminum pump has right (passenger) side intake (Figure 9b). Long shaft, requires deep pulley (Figure 5).See the water pump installation tech article. |