Poly 318 Pushrod Clearance Issues

Introduction

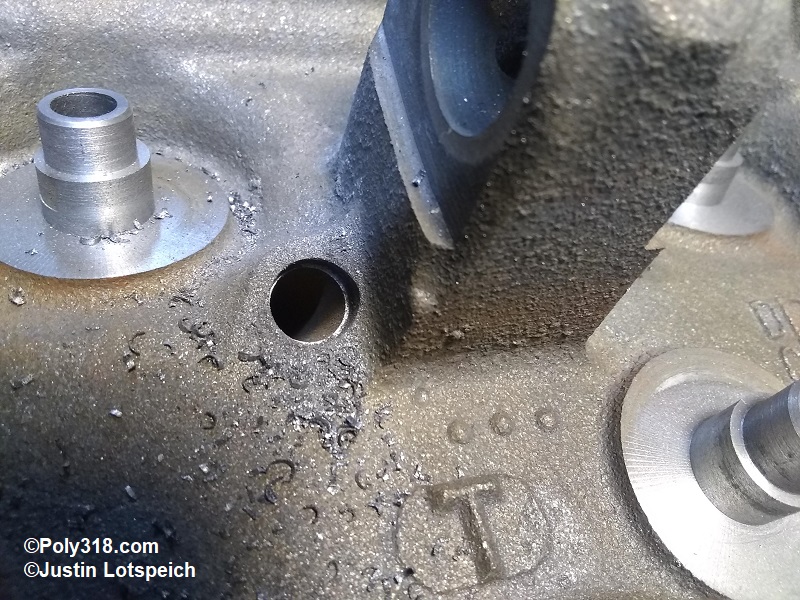

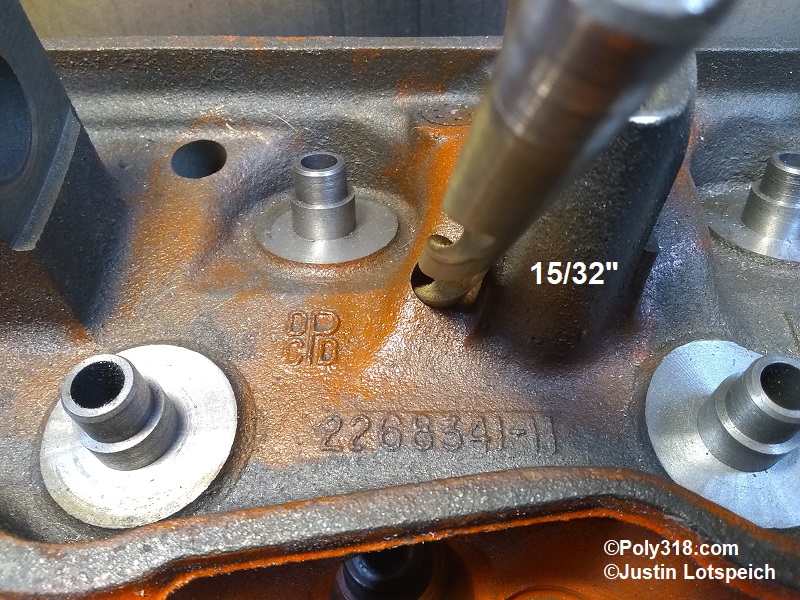

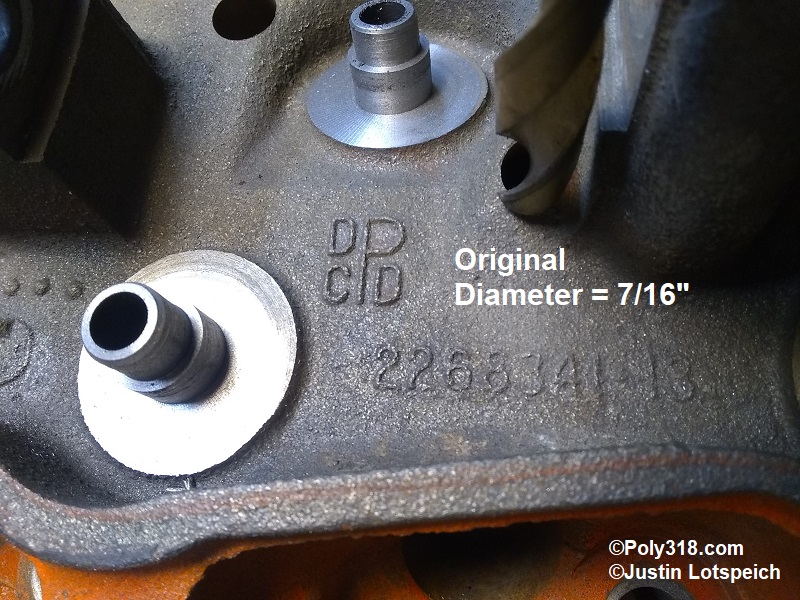

This article discusses a unique issue with the 1965 poly 318 cylinder head casting number 2268341-13 that can cause pushrods to rub, bind, bend, and break in some configurations. I discovered the issue when building a poly 390 stroker for my 1956 Dodge coupe. After completing the machine work on the heads for larger 2.02″ and 1.625″ stainless-steel valves and porting the heads, I noticed that the intake valve pushrod holes drilled through one of the heads were smaller in diameter than the other head. Both heads came off a virgin engine with a 1965 casting (1966 model year stamped ID) engine that had the original head gaskets, bearings, etc. and came out of a 1966 Plymouth Fury. One head was casting 2268341-11 with a date of February 1965, and both the intake and exhaust pushrod holes were drilled to 15/32″ diameter like every other A-block head I’ve seen from 1956 – 1966 (Figure 1). However, the other head was a casting 2268341-13 with a date of December 1965 with the intake valve pushrod holes drilled a smaller 7/16″ diameter (Figure 2). Out of curiosity, I pulled the valve covers off two other 1965 casting engines I have and found a similar situation with one of the heads being the same 2268341-13 with a date of November 1965 that also had smaller 7/16″ intake pushrod holes. The other three heads were 2268341-12 with the larger 15/32″ holes. While two heads on two different engines out of tends of thousands produced in 1965 isn’t enough for me to claim that all 2268341-13 heads have this issue, my observation and repair may help anyone rebuilding heads or who have pushrod clearance issues. It appears that for some reason, the 2268341-13 head manufactured in late 1965 into 1966 may have quality control issues with the intake pushrod holes not being drilled out to their final 15/32″.

Pushrods Rubbing, Binding, and Breaking

The issue with the smaller 7/16″ intake pushrod holes doesn’t seem to appear in stock engines but can become an issue with higher lift camshafts that move the pushrod at a different angle than shorter lift cams. For the poly 390 stroker, I’m running a .486″ lift camshaft. After mocking up the cylinder heads to measure for custom pushrods, I noticed that the adjustable pushrod length checker came extremely close to rubbing on the 7/16″ pushrod hole to where with heat expansion and under high revolutions it would likely rub.

Repairing the Issue

The repair is pretty straightforward: drill out the 7/16″ holes to 15/32″. It turns out the casting walls are likely no different than the previous versions since after I drilled out the holes I had no issue breaking through the runners. While the job can be done on a workbench with a handheld electric drill, I recommend jigging up the head on a drill press. Replacement pushrods can be purchased through Summit Racing, JEGS, Rock Auto, Napa Auto Parts, and through custom builders such as OE Pushrods or Smith Brothers.

- Secure the head on the drill press table shimmed to where a 7/16″ drill bit stuck in the pushrod hole is dead plumb and inline with the drill bit in the chuck.

- Using a sharp, quality 15/32″ drill bit long enough to go through the entire bore, drill out the hole. Because cast iron is hard on bits, use a slow motor speed, plenty of cutting fluid, and light pressure to allow the bit to work at its own pace. A dull bit, cheap bit, and/or forcing the bit may result in breaking off the bit (Figures 3 – 4).

- After drilling out the hole, use a 1/2″ drill bit or countersink to lightly chamfer the hole to remove the sharp edge.

- If the cylinder head does not need milling, use a flat sanding block and 120 grit sandpaper wet with oil to lightly knock down the rim around the hole on the gasket surface. If the head will be milled, skip this step.